Semi Auto Filling Machine for paste cream liquid

The semi-automatic filling machine is different from the fully automatic filling machine. The main function of the semi-automatic filling machine is filling. It rarely comes with other functions. Unlike the automatic filling machine, it can be equipped with conveyor belts, cap sorting machines, and capping machines. , Ancillary equipment such as inkjet printers, packing machines, and sealing machines

It is especially suitable for the filling of thick sauces such as chili sauce, bean paste, peanut butter, sesame paste, jam, butter hot pot base, red oil hot pot base and other substances with particles and high concentration.

Application

Tea is a kind of dry product, which can easily absorb moisture and cause qualitative changes. It has strong absorption of moisture and peculiar smell, and its aroma is very volatile. When tea leaves are stored improperly, under the action of factors such as moisture, temperature and humidity, light, oxygen, etc., adverse biochemical reactions and microbial activities will be caused, which will lead to changes in the quality of tea. Therefore, when storing, what container and method should be used , All have certain requirements. Therefore, the inner and outer bags are the best preserved and most used packaging.

Our packaging machine is the best machine for packaging tea.

Technical Parameters

|

Machine Model |

G1WY-100 |

G1WY-300 |

G1WY-500 |

G1WY-1000 |

G1WY-3000 |

G1WYG-5000 |

|

Filling Speed |

10-35n/min(take water for example). |

|||||

|

Filling Range |

10-100ml |

30-300ml |

50-500ml |

100-1000ml |

300-3000ml |

500-5000ml |

|

Air Pressure |

0.4~0.6mpa |

|||||

|

Filling Error |

±1% |

|||||

|

Machine Size |

806(L) × 180(W) ×690(H)mm |

880(L) ×230(W) ×665(H)mm |

880(L) × 230(W) ×665(H)mm |

1065 (L) ×230(W) ×665(H)mm |

1250(L) ×400(W) ×300(H)mm |

1390(L) ×420(W) ×380(H)6mm |

|

Machine Weight |

42 Kg |

45Kg |

48Kg |

52Kg |

64 Kg |

86 Kg. |

Note: the machine can be filled with 5L, suitable for non-particulate liquid and semi-fluid materials such as soy sauce, vinegar, liquor, lubricating oil, pesticide, shampoo, shower gel and hand sanitizer.

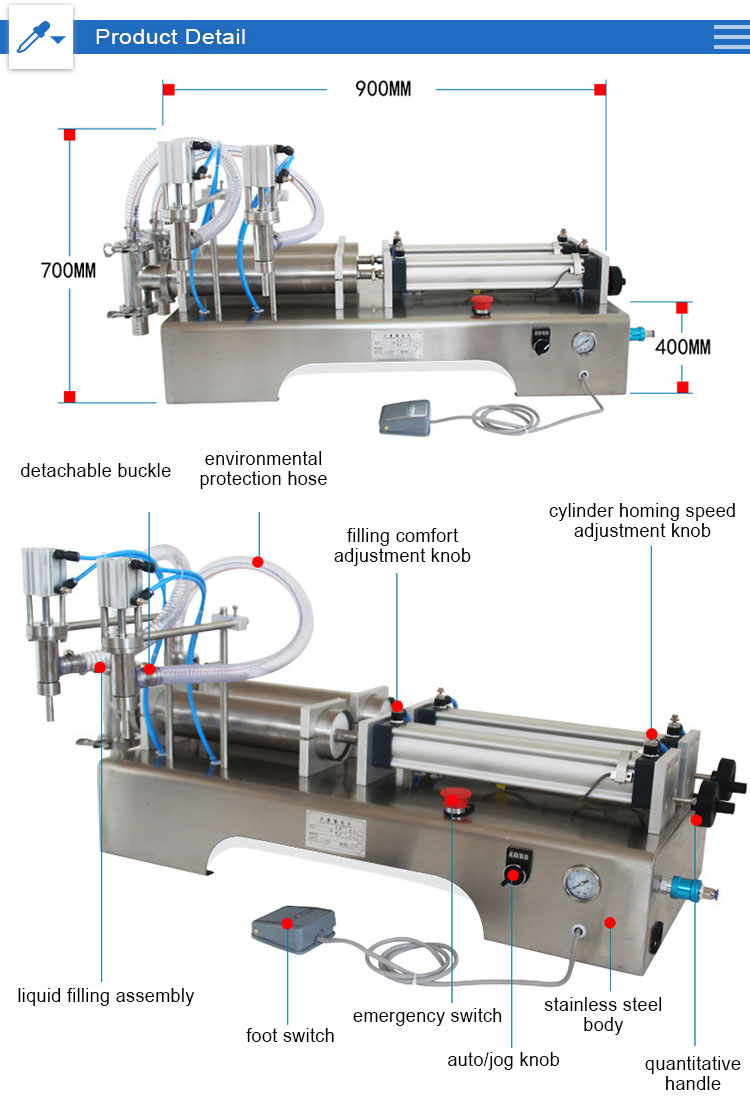

Principle

GFA series of semi-automatic filling machine piston filler. Driven by a cylinder and piston made from materials with FIVE-way valves control the flow of materials, and magnetic reed switch control cylinder itinerary can be regulated filling volume.

1. Rational design of the aircraft, model compact, easy to operate, are used pneumatic part of Germany and Taiwan AirTac FESTO the pneumatic components.

2. Some contact materials are used 316 L stainless steel materials, in line with the GMP requirements.

3. Filling volume and speed of filling can be arbitrary regulation, filling high accuracy.

QUALITY SHOW

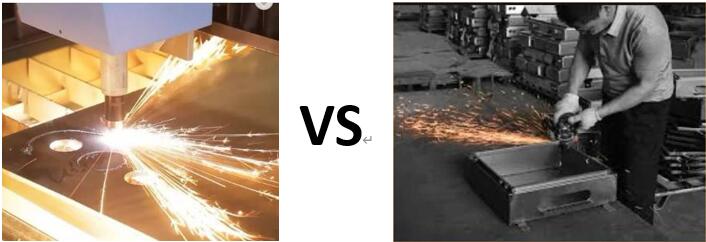

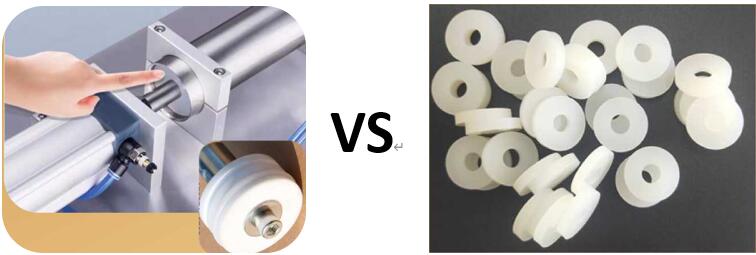

DIFFERENT CARVING CRAFT

CNC CUTTING

Ensure the precision of engraving, the compactness of machine combination and the precision of filling

HANDLE CUTTING

Imprecise for size, thickness, filling accuracy.

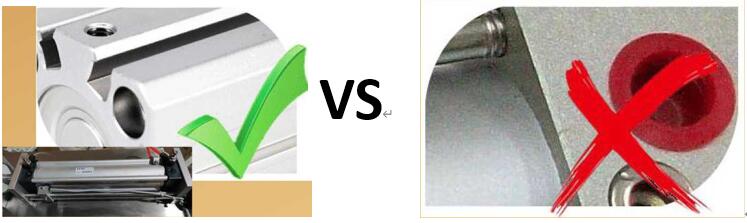

DIFFERENT AIR CYLINDER QUALITY

Taiwan Airtac air cylinder

Smooth surface, high-strength aluminum alloy

Ensure the maximum suction stroke, machine filling accuracy and stability

Ordinary cylinder

Unknown material, rough surface

Influence the working efficiency and accuracy

DIFFERENT POLISH TREATMENT

Do polish for both inside and outside hopper

Best protect the filling product safety &health

Low quality polish

Dirty the filled product

DIFFERENT QUALITY PISTON

Tetrafluoroethylene material, good sealing performance, corrosion resistance, high temperature resistance, not easy to deform,long service life

Poor stability and poor sealing effect

Result Low filling accuracy

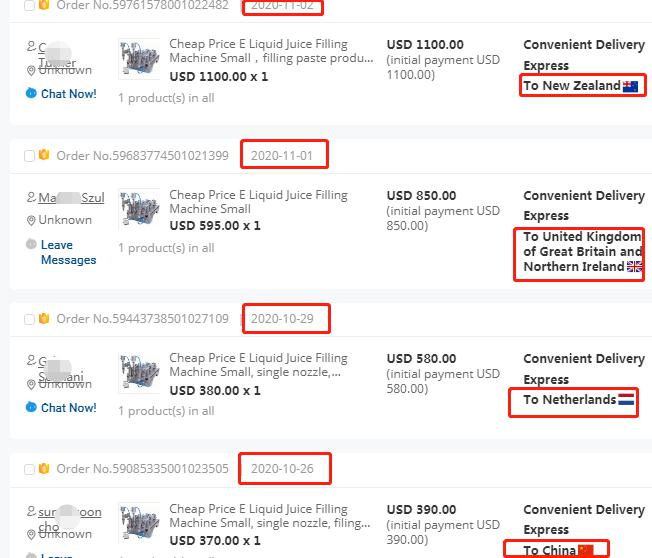

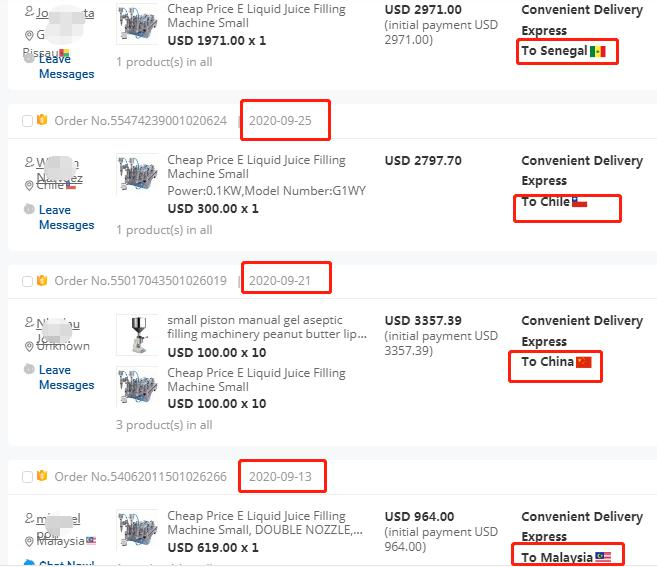

BUYER SHOW

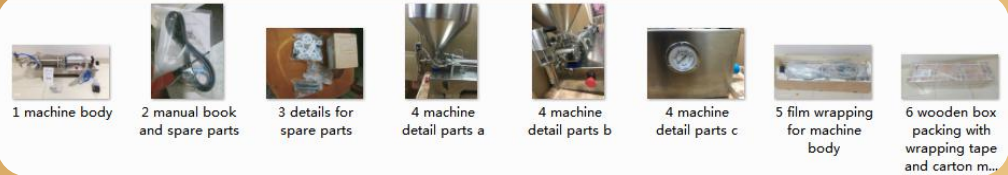

QC BEFORE SHIPMENT

1. PICTURE SHOW

2. TEST VIDEO SHOW

3. TEST REPORT SHOW

ASSEMBLY VIDEO SHOW (BEFORE SHIPMENT )

A: KEY PART DRAW

B. ASSEMBLE AND SETTING VIDEO SHOW

C. YOUTUBE LINK SHOW

QC GUARANTEE

① all filling or capping machine from our factory ,QC personnel will carefully check the quality of the machine and do power-on test before the package leaves the warehouse.

②all filling or capping machine from our factory , There are special QC equipment to help QC personnel complete the inspection.

③all filling or capping machine from our factory ,QC stipulates that after each inspection, the quality inspection report must be filled in to ensure the quality of customers' goods.

AFTER-SALES SERVICE

① all filling or capping machine from our factory ,24hours*365days*60minutes online service. engineers, online sales, managers are always online .

② all filling or capping machine from our factory ,We have a complete set of after-sales service process.

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③all filling or capping machine from our factory , If there are quality or other problems with our products,our company's team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

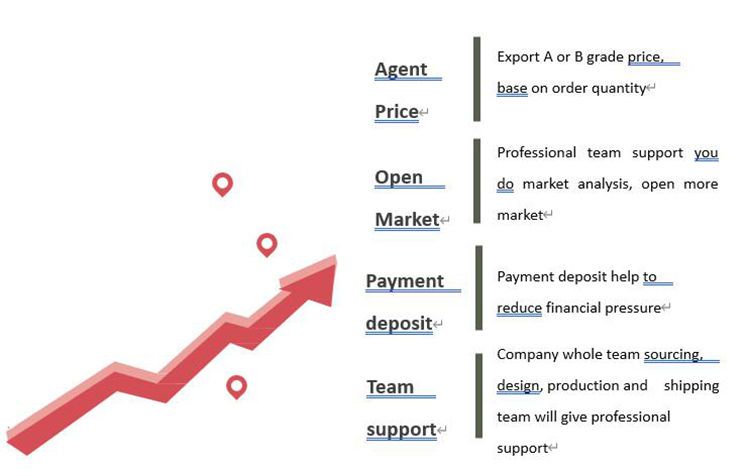

SPECIAL SERVICE FOR OUR AGENT

FAQ

1. Why choose us?

1.1- We have over 30 years experience on machinery making .

1.2- Our factory is located in Jiangsu province,more than 200 workers in our factory .

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit

our factory!

2.Can you customize machine ?

As a professional machinery manufacturer for more than 30 years,we have skilled OEM technique.

3. What about after sale service?

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video

or pictures. If the problem out of your control, we will arrange engineer to your factory.

4.How about warranty and spare parts?

We provide 1 year guarantee and enough spare parts for the machine,and most of the parts can be found in local market also,also you

can buy from us if all the parts that over than 1 year guarantee.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise

that our wooden packaging is strong enough and safety for long delivery .

6. What about the delivery time?

In stock machine:1-7days(depend on products).

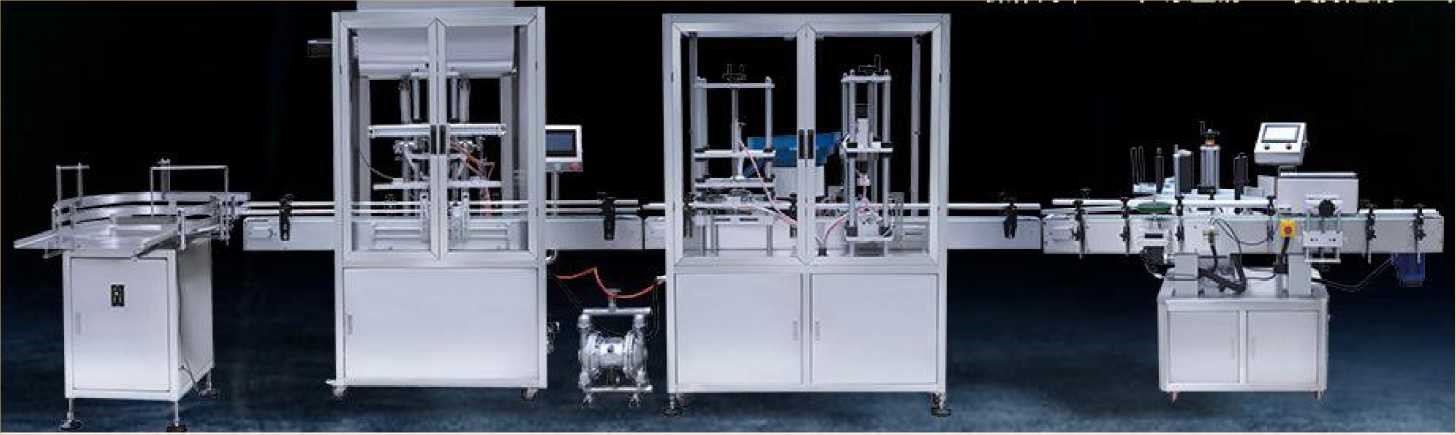

MORE CUSTOMIZED FILLING MACHINE

TABLE TYPE FILLING MACHINE

HIGH DISTANCE

MIXER FILLING MACHINE

Contact us know more filling machine for more type machine including semi auto filling machine,full auto filling machine , customized design filling system : filling machine , capping machine ,sealing machine , labeling machine ,packing machine