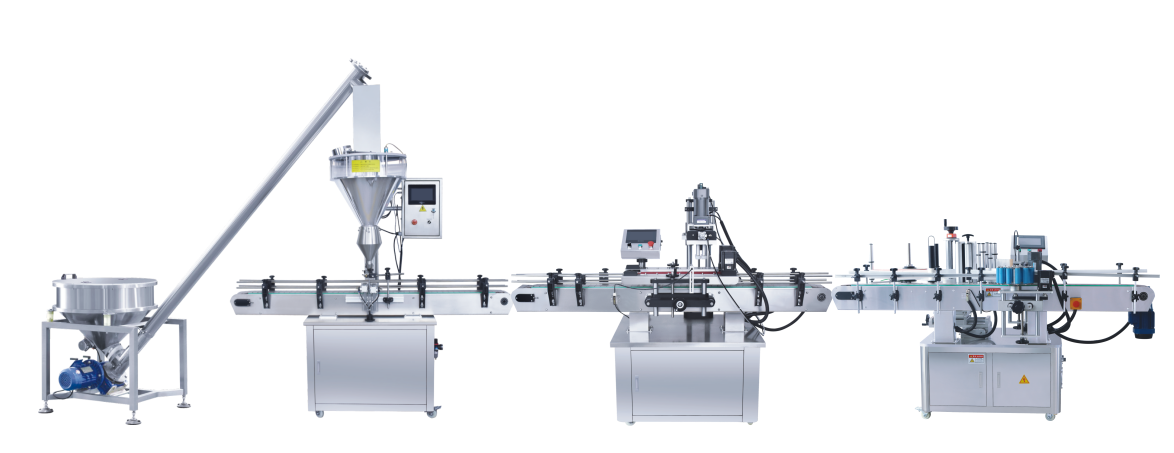

Powder Filling Capping Labeling Machine (Bottle Tin Container )

1. This powder filling machine integrates machine, electricity, light and instrument. It is controlled by single chip microcomputer and has the functions of automatic quantitative, automatic filling and automatic adjustment of measurement error.

2. Fast speed: using screw cutting and light control technology

3. High precision: using stepper motor and electronic weighing technology

4. Wide range of filling and filling: the same quantitative filling machine can be adjusted continuously within 5-5000g through electronic scale keyboard adjustment and replacement of feeding screws of different specifications

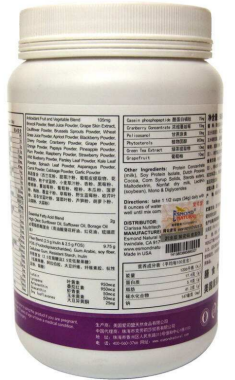

5. Wide range of application: powder and granular materials with certain fluidity can be used

6. Suitable for quantitative packaging of powders in various packaging containers such as bags, cans, bottles, etc.

7. Errors caused by material specific gravity and material level changes can be automatically tracked and corrected

8. Photoelectric switch control, only need manual bagging, the bag mouth is clean and easy to seal

9. The parts in contact with the material are made of stainless steel, which is easy to clean and prevents cross-contamination

|

|

|

|

|

|

|

|

|

|

|

|

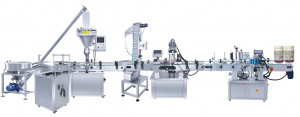

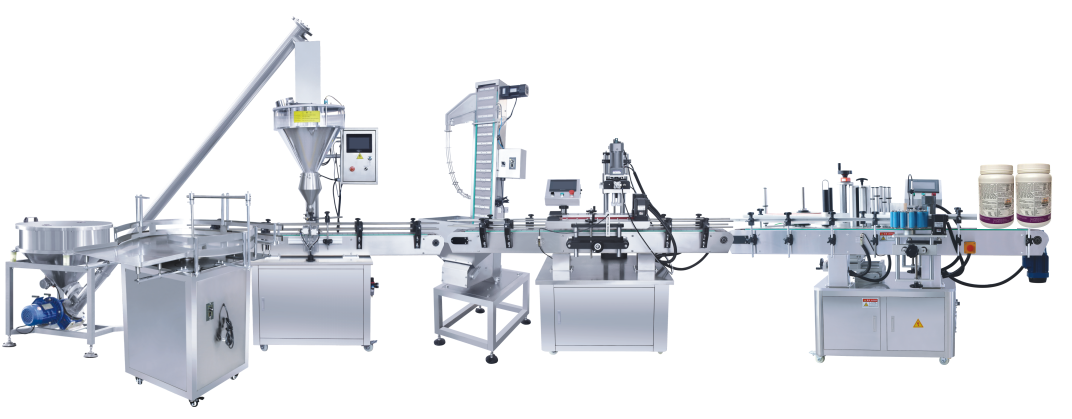

AUTOMATIC LINE FOR POWDER

PERFORMANCE AND FEATURES

- the equipment material for the quality of 304 stainless steel , in line with GMP requirements

- The device outlet with a vacuum device , the external dust cover

- The container automatically positioning , automatic filling materials

- PLC touch the filling volume and filling speed can be adjusted arbitrarily with high precision

- Can automatically display the number of packaging , can be convenient to calculate the workload of the machine

INDEPENDENT UNSCRAMBLER

INDEPENDENT POWDER FILLING MACHINE

| Model | BLT-730 | BLT-710 | BLT-700 |

| Packing material | powder | powder | powder |

| Filling weight | 10-2000g | 10-1000g | 1-10g(D14mm nozzle)

10-30g(D23mm nozzle) |

| Power | 1.8kw | 1.25kw | 0.92kw |

| Hopper capacity | 75L | 25L | 6L |

| Filling speed | 30-50 bottles/min | 1-30 bottles/min | 10-20 bottles/min |

| Machinery size | 3000x1060x2000mm | 900x900x2000mm | 500x400x1000mm |

| Machinery weight | 150kg | 100kg | 60kg |

AUTO SEALING MACHINE

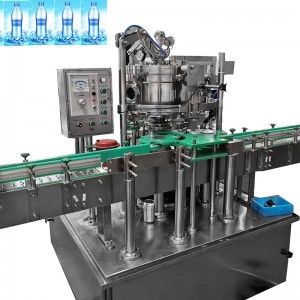

| Model | CAPPING MACHINE |

| power | 0.75kw |

| speed | 30-60pcs |

| Air pressure | 0.4-0.6MPA |

| Machinery size | 2000X1400X1600mm |

| weight | 250kg |

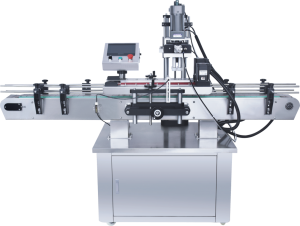

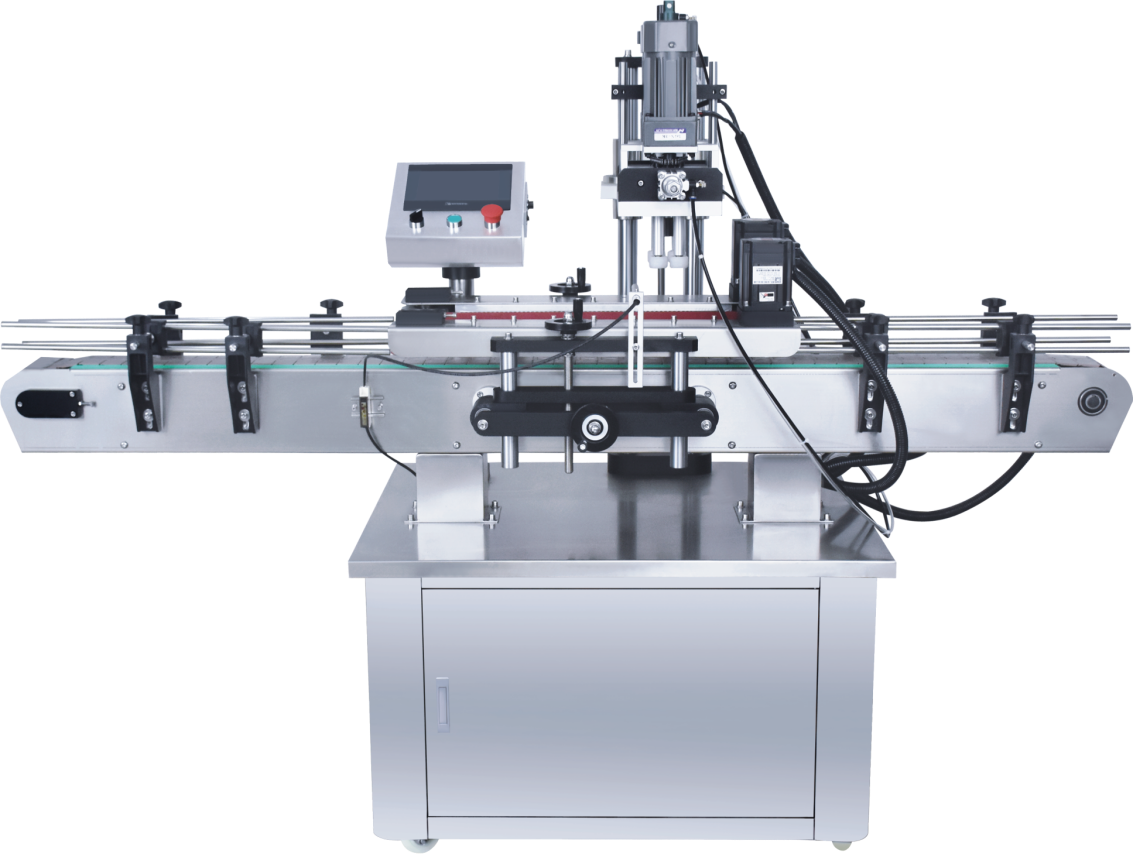

AUTO LABELING MACHINE

| Model | LABELING MACHINE BLT-220 |

| Speed | 20-200pcs/min (depend on bottle size) |

| Bottle size | D30-120mm |

| Label height | 15-200mm |

| Label length | 25-300mm |

| ID of paper core | 76mm |

| OD of label | 350mm |

| power | Single phase 220v 1.5kw 50/60HZ |

| Air request for printer | 0.5Pa |

| Machinery size | L2000xW1400xH1300mm |

| Machinery weight | 200kg |

PS : Beverage filling machine, beverage filling machine is a plastic bottle beverage filling machine, automatic filling and capping machine, is a multi-functional beverage filling machine. It is used for filling carbonated beverages, soda water, salt soda and other carbonated beverages, as well as non-sparkling beverages such as fruit juice beverages and purified water. One machine has multiple functions and is a new type of filling machine with high practicability.

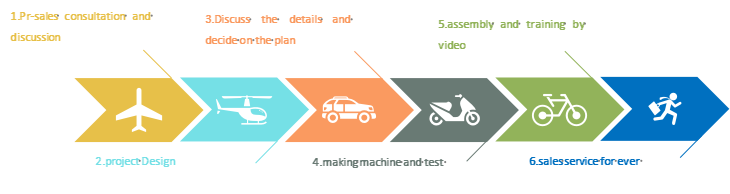

Welcome contact in any time ,customized line is our advantage

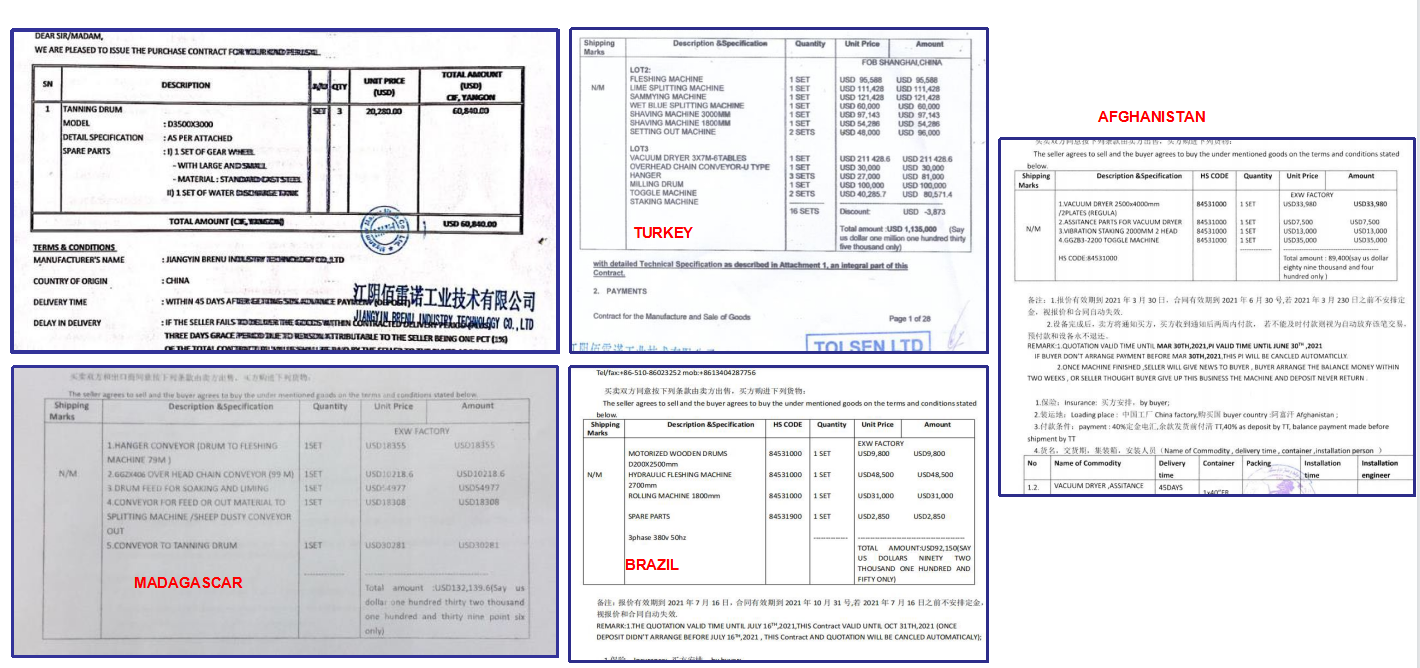

BUYER FEEDBACK

MORE CHOOSE FOR POWDER LINE

A. FILLING MACHINE +CAPPING MACHINE

B. FILLING +CAPPING +LABLING

C. FILLING+SEALING+CAPPING

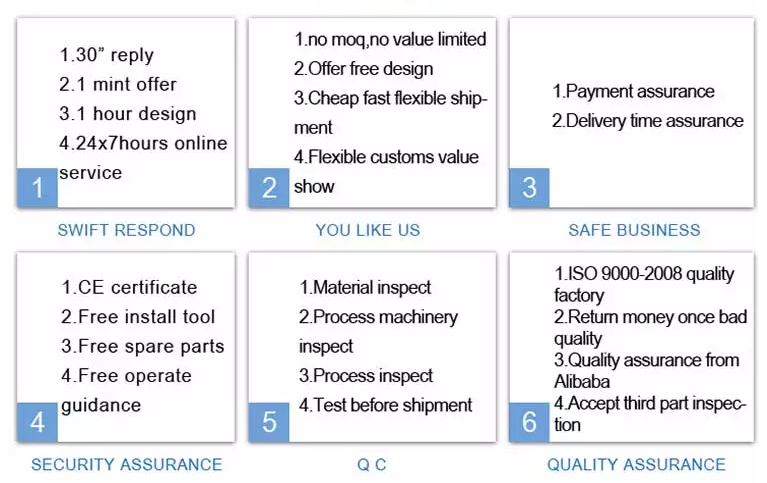

BRENU SERVICE

COMPANY INTRODUCE

TOP 10 SUPPLYER IN ALIBABA JIANGYIN BRENU INDUSTRY TECHNOLOGY CO.,LTD LOCATED THE CENTRA POSITION OF CHINA , OUR MAIN PRODUCTION SPECIAL FOR FOOD , PHARAMACY , COSMETIC INDUSTRY.

BASE OURSELF PRODUCTION ,RESOURCE INTEGRATION IS OUR ADVANTAGE FROM UPSTREAM AND DOWNSSTREAM FIRM, DESIGN DEPARTMENT AND PROJECT DESIGN ARE MOST IMPORTANT OF BRENU .

MAIN PRODUCTION INCLUDING :MANUAL OR AUTO TYPE BOTTLE UNSCRAMBLER , FLIING MACHINE , CAPPING MACHINE , LABELING MACHINE , SEALING MACHINE , HOT SHRINK MACHINE , VACUUM DRYER , CARTON MACHINE , PACKING MACHINE , WRAPPING MACHINE AND CARTON SEALING MACHINE . WE SUPPLIED THE TURN KEY PROJECT FOR MORE THAN 30 COMPANYS .

AT THE SAME TIME , WE SUPPLY FREE CUSTOMIZED DEISGN FOR THE PACKING FILM , PLASTIC BOWL ,CUP , LABLE AND SO ON .

ALL OF MACHINERY MADE BY FOOD TYPE MATERIAL, ALL PRODUCTION PASS CE CERTIFICATE , PRODUCTION PASS ISO9001 CERTIFICATE , ALL OF MACHINERY PASS VERY SERIOUS INSPECTION BEFORE EXPORT .

OUR PRODUCTION WERE EXPORTED TO MORE THAN 100 COUNTRIES , SPECAIL IN EUROPE ,MIDDLE COUNTRY , ASIA AND SO ON .

BRENE PRODUCTION ALWAYS FOLLOW MARKET REQUEST , JUST RECOMMEND BUYER REQUEST AND MOST STUITABLE ONE .

OUR PROMISE

SALES SERVICE ON LINE:

① 24hours*365days*60minutes online service.

② team contact information for service .

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③ If there are quality or other problems with our products,our company's team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

MACHINERY PARTS GUARANTEE :

Our company guarantees that all parts of the machine are original and authentic. During the one-year warranty period, our company will provide customers with free replacement parts and consumables for non-human damaged parts and consumables. Replacement is available to customers at cost price. Our company promises to provide life-long service for customer equipment, and only charge basic material costs and corresponding labor costs outside the warranty period.

CHOOSE US YOU ARE BEST CHOICE :

SHOW OUR SERVICE TEAM PICTURE :

SHOW OUR GUARANTEE CERTIFICATE FROM CEO :

CUSTOMER SHOW :

Welcome contact :

what's app:0086 13404287756

Quality guarantee :trade assurance by alibaba by manager and CEO

trade assurance protect : your money , delivery time and quality

JIANGYIN BRENU INDUSTRY TECHNOLOGY CO.,LTD

skype:belinna_2004mail:sales@brenupackmachine.com www.brenupackmachine.com