Premade Pouch Machine With Mix Weight Filling Sealing For Grain

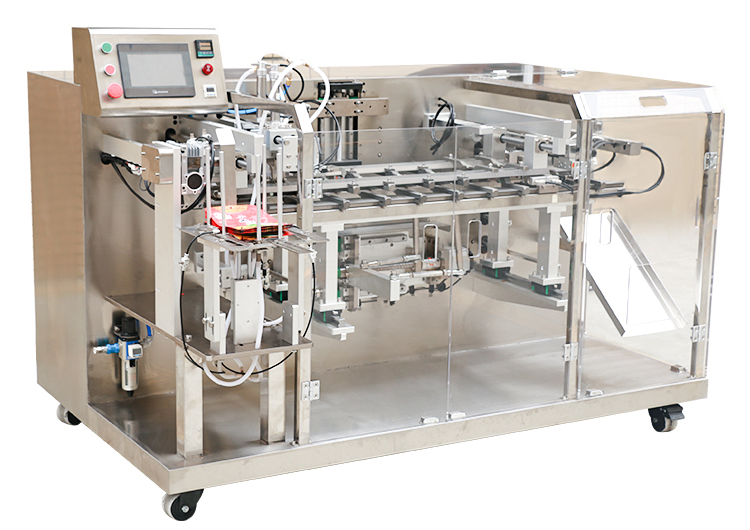

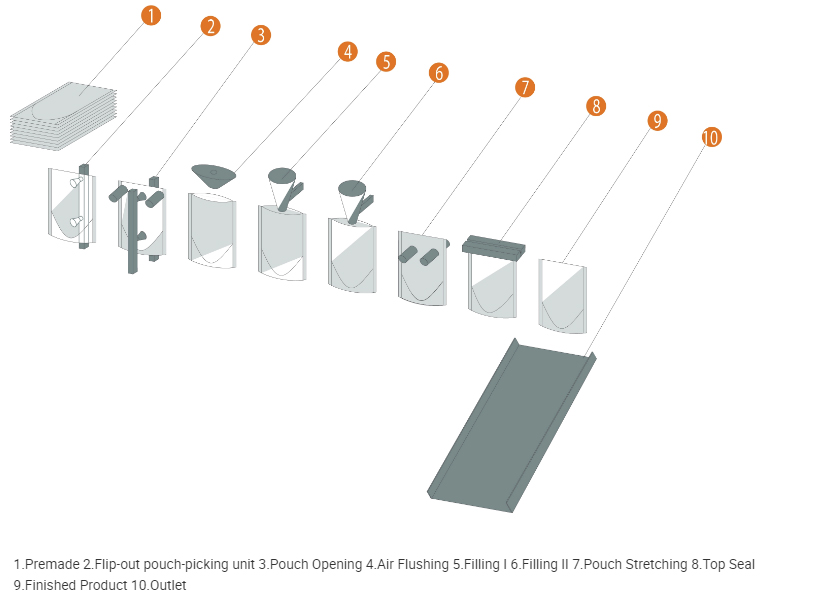

The premade bag automatic packaging machine replaces manual packaging, and realizes packaging automation for large enterprises and small and medium-sized enterprises. The operator only needs to put the finished bags one by one, and put hundreds of bags in the bag removal department of the equipment at a time. , The mechanical claw of the equipment will automatically take the bag, print the date, open the bag, give a signal to the measuring device, and blank, seal, and output.

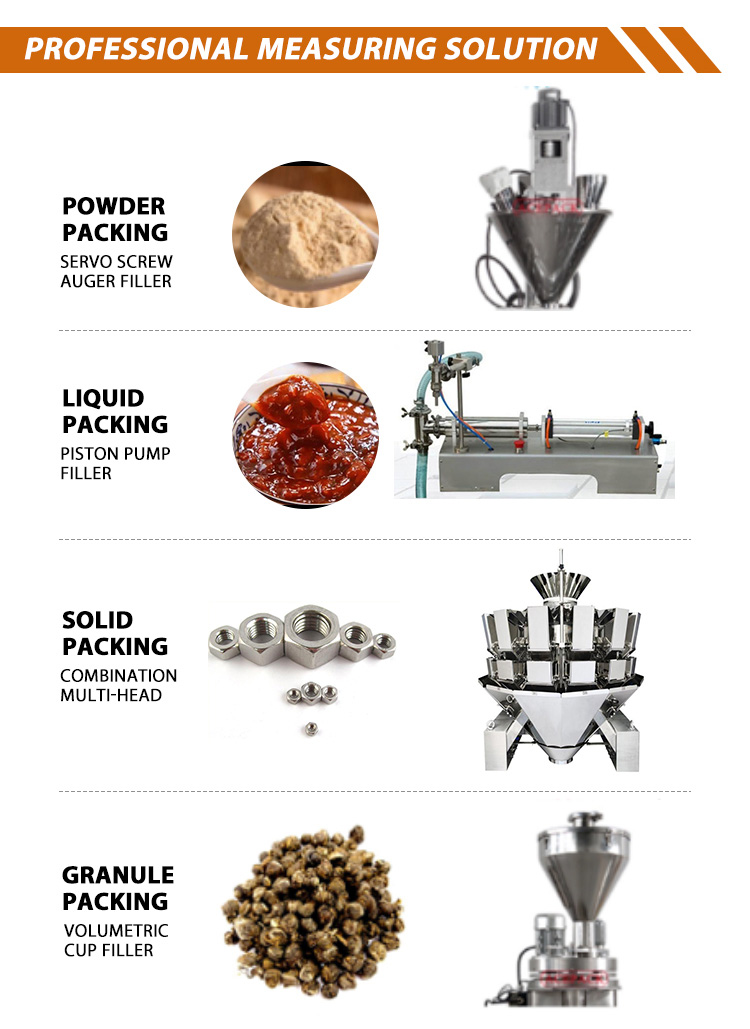

THE FILLING SYSTEM IS JUST FOR YOUR REFERENCE ,WE WILL OFFER YOUR BEST SOLUTION ACCCORIDNG TO YOUR PRODUCT MOBILIT , VISCOSITY, DENSITY , VOLUME ETC

A. POWER PACKING SOLUTION

Servo screw auger filler is special for powder like ,milk , spice ,flour , medicine etc

B. LIQUID PACKING SOLUTION

Piston pump filler is specialized for liquid fill such as water ,juice , laundry detergent,shampoo , lotion , paste , jam and so on .

C. SOLID PACKING SOLUTION

Combination multi-head weight is special for solid filling , such as , candy , nuts , dry fruit ,snack,etc

D. GRANULE PACKING SOLUTION

Such as chemical , beans ,salt , rice and so on

A. Premade Bag Powder Filling Machine

Machinery Detail

1.Whole machinery run controlled by servo system , ensure machinery , run steady , precision and steady

2.Top brand international electric parts , get local service

3.The speed of this machine is adjusted by frequency conversion with the range, the actual speed depends on type of production and pouch size

4.Automatic checking system for bag situation , filling and sealing situation ,mention you once 1.no bag feeding, 2. no filling and no sealing 3. bag no open

|

Model |

BMD-210K |

|

Working speed |

15-45 bags/min(difference for more material) |

|

Bag capacity |

1-100g(base on difference goods) |

|

Weight precision |

±0.2g-3g(base on difference goods) |

|

Control system |

Full servo system with PLC touch screen |

|

Acceptable bag width |

80mm-210mm |

|

Acceptable bag length |

80mm-280mm |

|

Bag type |

4 side sealing machine |

|

Sealing method |

Heat sealing |

|

Bag material |

PP,PE,PVC,PS,EVA,PET,PVDC+PVC,OPP+CPP and others |

|

Power |

3P AC 380v/ 50Hz/60HZ 3.2KW |

|

Air request |

0.6m3/min,0.6-0.8Mpa |

|

Weight |

1200kg |

|

Dimensions |

3600x1800x3750mm |

PS: doypack ,zipper bag ,t-shirt bag , paper bag with professional structure ,welcome mention sales before order

Extra device :zipper open , air ,code print ,special shape cut and other ,welcome mention sales

B. Weighting And Filling System

|

Model |

BMD-10 |

|

Weight per time |

10-1500g(difference for more material) |

|

Weight precision |

±0.5g-2g(base on difference goods) |

|

speed |

65bpm |

|

Tank capacity |

2500ml |

|

Control system |

Touch screen |

|

Power |

220v/ 50Hz/60HZ 10A/1000W |

|

Weight |

400kg |

|

Dimensions |

1620x1100x1100mm |

| MODEL | BMD-2-2 Electric weight plate |

| Max loading weight | 2T-3T |

| Dimensions | 1800mm*1800mm*1800mm |

| Weight | 350kg |

| Model | MD-350 Z type lift+ vibration tank |

| power | 750W |

| max drive speed | 4000kg/h (rice) |

| Dimensions | 3000(L)x650(W)x3750(H)mm |

FAQ:

1.What guaranteeing does BRNEU offer?

One year on non-wear parts and labor. Special parts discuss both

2. Do installation and training included in the machinery cost?

Single machine:we done installation and test before ship, also supply competently video show and operate book ; the system machine :we supply installation and train service , the charge not in the machine , buyer arrange tickets , hotel and food ,salary usd100/day )

3. What types of packaging machines does BRENU offer?

We offer complete packing systems that including one or more of the following machines , also offer manual , semi-auto or full auto line machine . like crusher ,mixer , weight , packing machine and so on

4. How does BRENU ship machines?

We box smaller machines, crate or pallet larger machines. We ship FedEx, UPS, DHL or air logistic or sea , Customer pickups are protected well. We can arrange partial or full container shipping.

5. How about the delivery time ?

All small regular single machine ship in any time , after test and packing well .

Customized machine or project line from 15days after confirmed the project