OEM Manufacturer Vacuum Container Cup Sealing Machine - Manual Filling Machine with air push for lipgloss – BRENU

OEM Manufacturer Vacuum Container Cup Sealing Machine - Manual Filling Machine with air push for lipgloss – BRENU Detail:

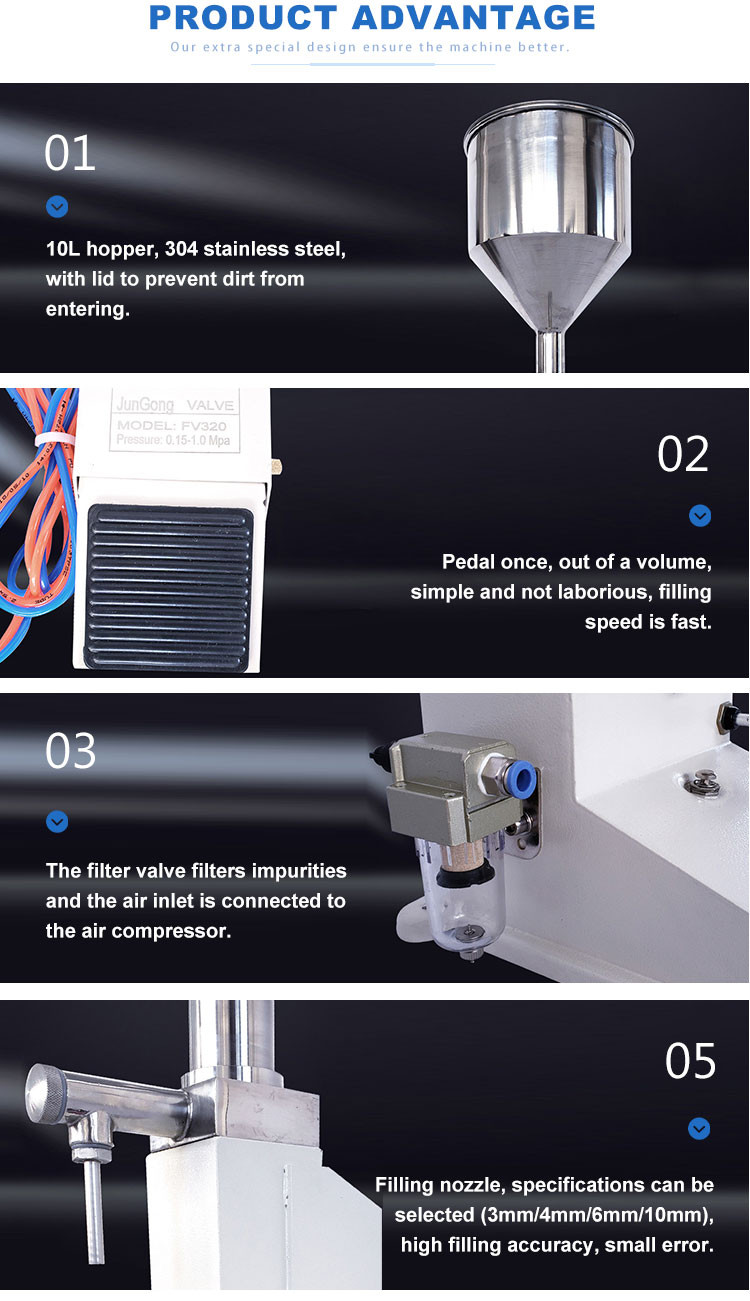

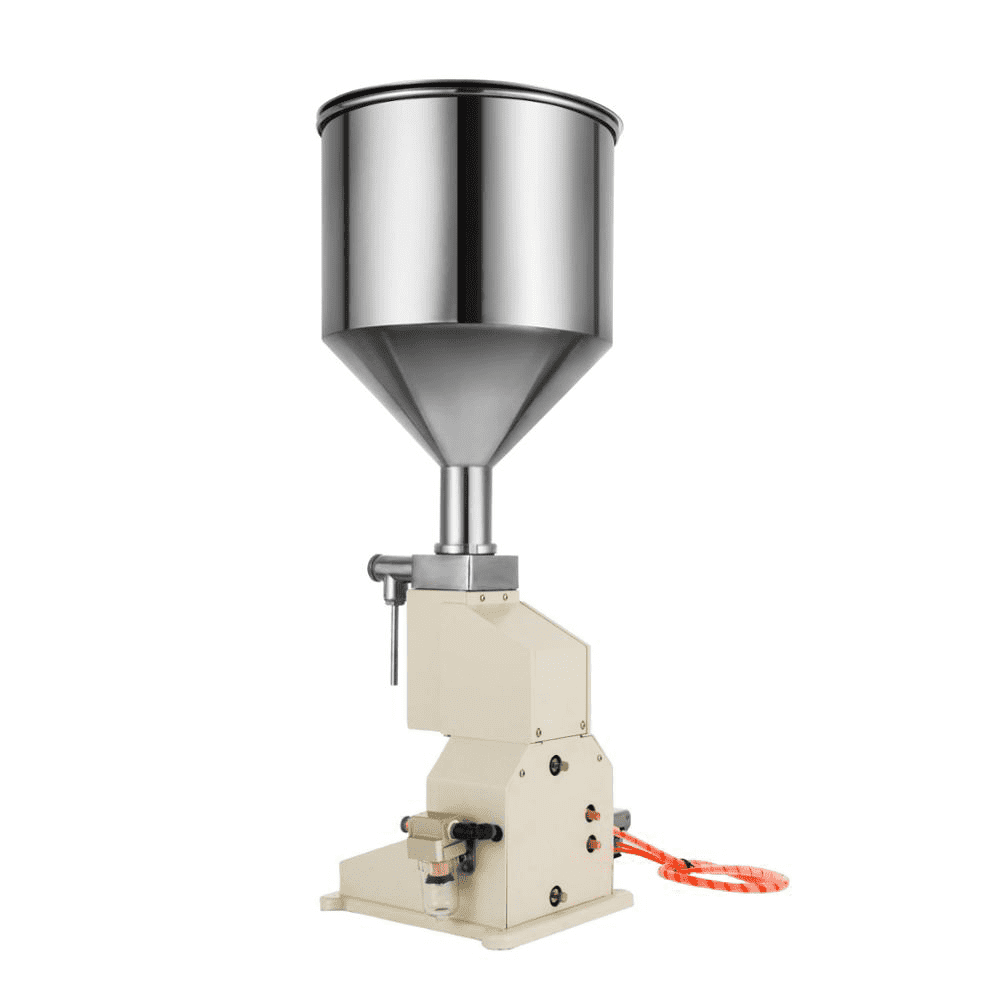

The hand pressure filling machine is a manual piston liquid filling machine.with air push , can for some paste with stick , It can be filled with liquid medicine, liquid food, lubricating oil, shampoo, shampoo and other cream/liquid substances, and has the function of a cream liquid filling machine. Its structure is simple and reasonable, and manual operation is convenient. No energy is required. It is suitable for medicine, daily chemical, food, pesticide and special industries. It is an ideal liquid/paste filling equipment. The material contact parts are made of 316L stainless steel, which meets GMP requirements. The filling volume and filling speed can be controlled manually.

Description

Pneumatic B02 type manual filling machine is based on the manual filling machine B03 to improve, driven by compressed air, with the foot switch and automatic switch, the complete liberation of the user’s hands, make the operation more convenient. The product is designed for hospitals, laboratories, beauty salons, small and medium enterprises, such as design, ideal for filling small doses of liquid and paste.

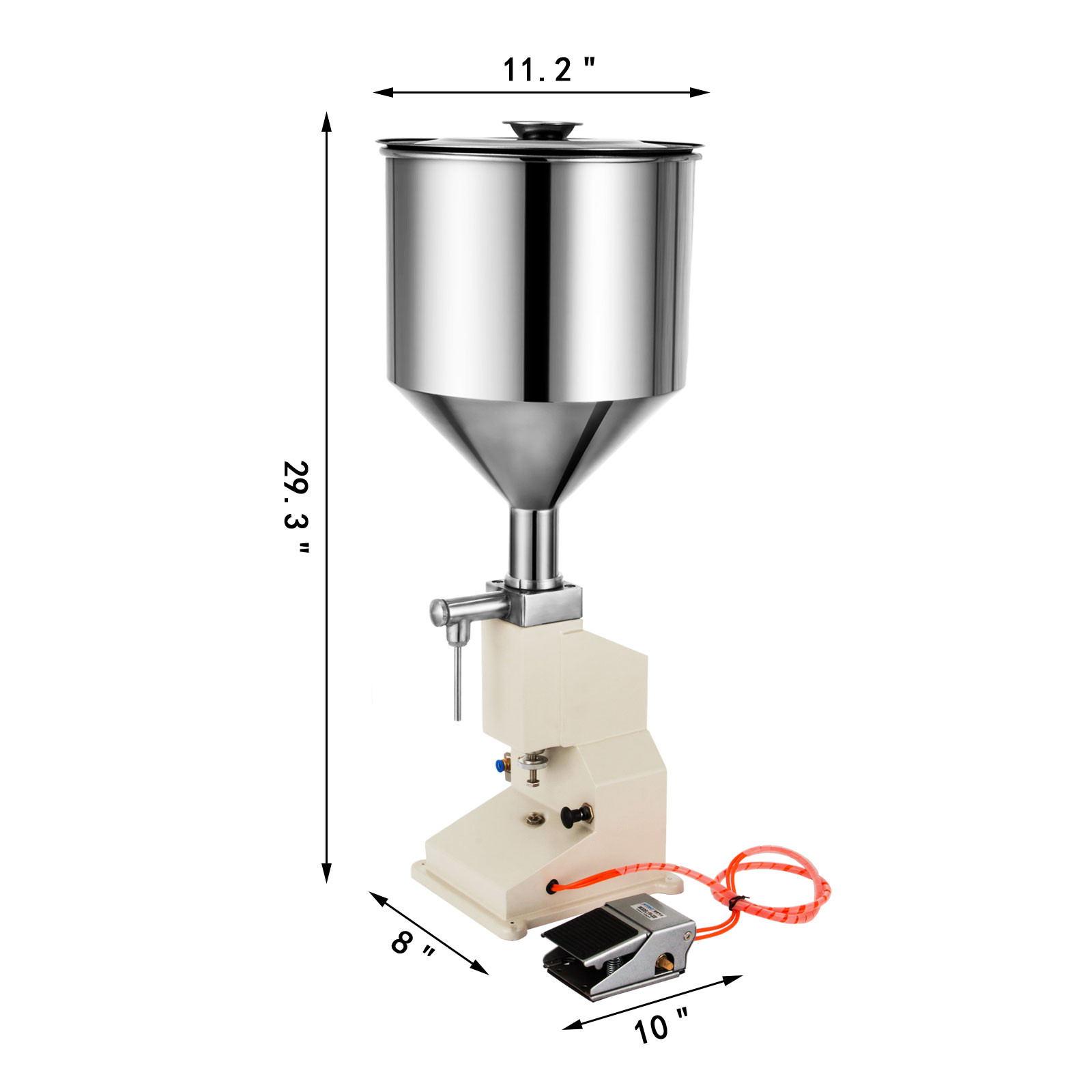

| Material of machine | Stainless steel 304 |

| Filling Range | 5-50 ml |

| Capacity of Hopper | 10 kg |

| Filling Accuracy | ± 0.2-1ml |

| Filling Speed | 20-60times/min (It varies from person to person) |

| Working Pressure | 0.4-0.6Mpa |

| Net Weight | 18 kg |

| Gross Weight | 22 kg |

| Machine Size | 340x340x780 mm |

| Packing Size | 370×370×800 mm |

HAIR CREAM

USA BUYER

A great man, always working hard every day !! Order 3 times to increase his product filling.

LIP GLOSS

COLUMBIA BUYER

A Beauty and kindness girl, order machine for self also for her friends as gift.

PEANUT BUTTER

JAPAN BUYER

A very rigorous boss, thanks for his good feedback in alibaba.

AGENT

NIGERIA BUYER

A happy and great mother, has 3 daughters. Do wholesale in local, order every month.

QC GUARANTEE

① all filling or capping machine from our factory ,QC personnel will carefully check the quality of the machine and do power-on test before the package leaves the warehouse.

②all filling or capping machine from our factory , There are special QC equipment to help QC personnel complete the inspection.

③all filling or capping machine from our factory ,QC stipulates that after each inspection, the quality inspection report must be filled in to ensure the quality of customers’ goods.

AFTER-SALES SERVICE

① all filling or capping machine from our factory ,24hours*365days*60minutes online service. engineers, online sales, managers are always online .

② all filling or capping machine from our factory ,We have a complete set of after-sales service process.

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③all filling or capping machine from our factory , If there are quality or other problems with our products,our company’s team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

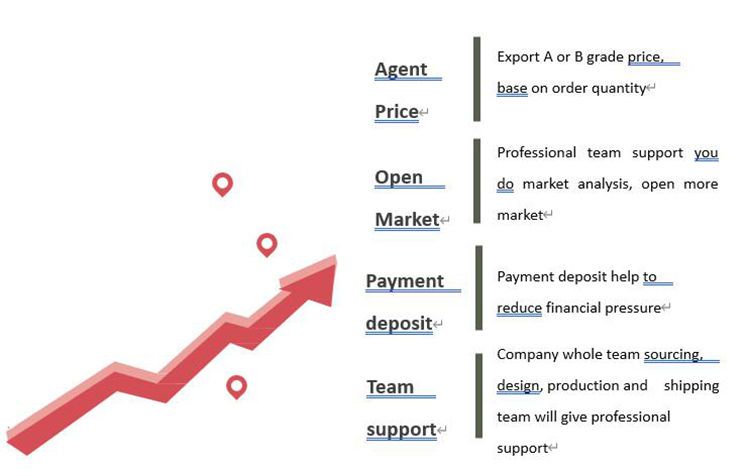

SPECIAL SERVICE FOR OUR AGENT

FAQ

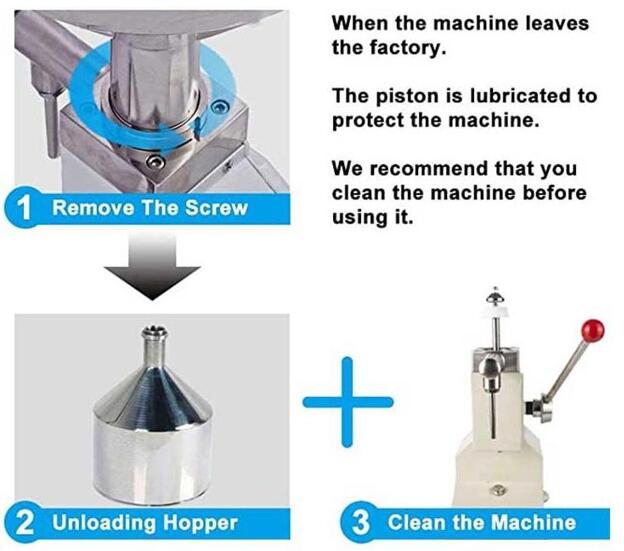

1. HOW TO CLEAN THE FILLING MACHINE ?

when the filling machine leaves the factory , the piston is lubricated to protect the machine , we recommend that you clean the machine before using it .

2.How to Adjust filling range?

3.What’s the easy consumer spare parts?

Package Content:

A03 Manual Filling Machine X1.

Nozzles(4mm/8mm)X1.

O-Rings

Inner hexagon spanner X2.

Guide Manual X1.

Can order more rings for backup.

4. AMAZON Price for filling machine much more cheaper than you, why order from you?

01.amazon goods always in amazon stock , difficult test the machine show the video with the similar production with you .

Amazon service person help arrange the machine to you door ,but difficult second time check test and packing for you , even difficult to know the situation of the filling machine before send to you ,even difficult show you the packing process

More important , we supply technical support for ever , service team 24hours online

MORE CUSTOMIZED FILLING MACHINE

Contact us know more filling machine for more type machine including semi auto filling machine,full auto filling machine , customized design filling system : filling machine , capping machine ,sealing machine , labeling machine ,packing machine

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for OEM Manufacturer Vacuum Container Cup Sealing Machine - Manual Filling Machine with air push for lipgloss – BRENU , The product will supply to all over the world, such as: Guatemala, Angola, Danish, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!