See the machinery we recommend , although looks simple , but in side material special , special in filling machine ,

The product adopts real-time weighing detection control, which can accurately detect the actual weight of the filling material, and is not affected by factors such as material density, temperature, bubbles, impurities, and mixtures. It is the most recognized and clearly displayed metering control mode.

Manual and automatic can be converted, when the automatic system fails. Filling can be done manually with minimal impact on production.

Using multi-flow filling technology, fast filling in the early stage and slow filling in the later stage to ensure filling accuracy and prevent foam overflow.

Anti-drip oil nozzles are used to prevent contamination caused by residual droplets.

The counting device is processed by a special program to prevent the wrong number of barrels from being counted, and the filling nozzle will not be in place.

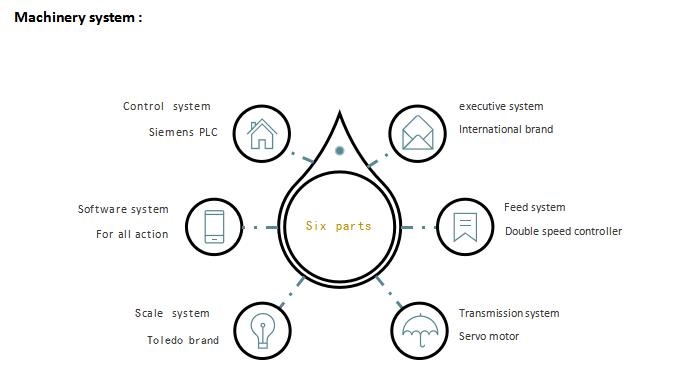

Filling machine special :

Plz see our buyer machinery run for chemical filling ,capping and labeling :

Do you care how much for this filling machine capping machine and sealing machine line ?

If you contact us , we must give special price ,what’s app :+8613404287756

① 24hours*365days*60minutes online service.

engineers, online sales, managers are always online.

② We have a complete set of after-sales service process.

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③ If there are quality or other problems with our products,our company’s team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

Post time: Apr-11-2022