Automatic Liquid Capsule Filling Machine

automatic hard-capsule liquid filling machine and sealing linkage line .the device can complete the filling of hard capsules (solution, suspension, microemulsion or hot solution) and sealing the capsule cap joint to make the capsule The contents are sealed in the process of packaging,transportation and use, which improves the stability and safety of the product. It can provide new modes of administration, improve the drug delivery problems of many drugs, and fill the domestic and foreign pharmaceutical and health care.

automatic hard-capsule liquid filling machine and sealing linkage line .the device can complete the filling of hard capsules (solution, suspension, microemulsion or hot solution) and sealing the capsule cap joint to make the capsule The contents are sealed in the process of packaging,transportation and use, which improves the stability and safety of the product. It can provide new modes of administration, improve the drug delivery problems of many drugs, and fill the domestic and foreign pharmaceutical and health care.

Product performance, features:

1. The equipment adopts man-machine interface control system, which automatically lacks capsules and lacks material alarm. 2. The capsule feeding machine has a vacuum positioning and separating mechanism, so that the probability of the capsule is over 99%. The fiber is automatically detected, and the capsule is missing in the upper and lower mold holes.

3. High-precision ceramic pump and servo motor dosing system are adopted to control the difference of the loading amount to about ±2%, and the dosage is accurate. 4. The sealing mechanism adopts the servo motor lifting device, which can be used to jog and fine-tune the rubber wheel to achieve the best effect of the sealing layer.

5. The sealing liquid tank is designed as a sealing structure, and is equipped with a heating and heat preservation system to ensure the viscosity of the glue liquid and effectively extend the glue liquid period. 6. The finished dry curing mold adopts hanging type and free rotation structure, which effectively improves the disassembly and unloading cleaning time.

|

Model |

BNJYF-300C |

|

Yield |

18,000 tablets / hour |

|

Sealable capsule filling |

Solution, suspension, microemulsion |

|

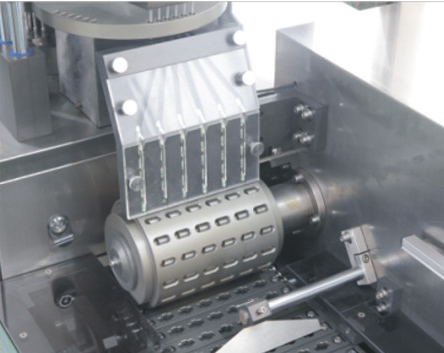

Mold hole number |

6 holes |

|

Applicable capsule |

00-4# gelatin, plant capsule |

|

Environmental requirements |

Room temperature around 20C, humidity 40% -55% |

|

voltage |

Three-phase 380V/220V 50Hz |

|

Total power |

9KW |

|

Compressed air |

0.6Mpa |

|

Total weight |

2300KG |

|

Dimensions |

3800*900*1900MM (length × width × height) |

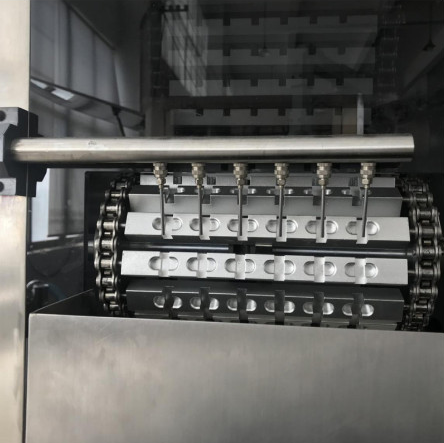

The 10-station rotary disc adopts integrated processing to achieve com[act structure , no splicing gap , good sealing ,easy to disassemble and easy to maintain , the fixed bracket shaft seal of the upper and lower modules adopts the oil-proof and dust-proof double-lip bone dust-proof ring , it can be repaired and maintenance free without any dry sound , small volume, small load and high precision fully enclosed rotary disc .

High precision ceramic pump

The liquid filling mechanism adopts a high -precision ceramic pump and a servo motor dosing system to control the difference in liquid material loading in the capsule to about 2%

Rotary type capsule-out

The rotary type capsule out mechanism used the mold turntable and the capsule-out turntable to perform synchronous work to ensure that capsules in each set of die holes are evenly and orderly converted into the bag-out turntable

High precision fiber inspection system

Due to the fast reaction speed , the fiber-optic sensing can realize non-contact detection with high precision , high resolution and good reliability , the device can quickly detect whether the hollow capsules are normally separated during the production process , such as non-normal un- separated hollow capsule , optical fibbers , after the system detects the collected date to the filling station and the kicking station ,the equipment runs to the filling station , according to the date analysis of the fiber inspection system , the filing station stops adding liquid , and the equipment runs to the kicking station ,the abnormal um-separated hollow capsules are removed to ensure the stability of the equipment during the production process

Capsule introduction mechanism

Capsule introduction mechanism , with capsule automatic guiding , optical fiber detection in the capsule plate , capsule high and low position to control the speed synchronization function between the host and the auxiliary machine in real time

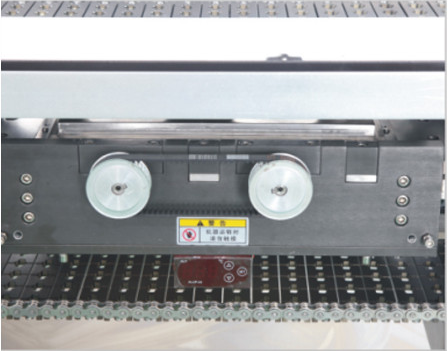

Gel sealing system

The lifting and sealing gel tray adopts the servo motor control system and the sealed storage glue to effectively prevent the glue from evaporating in the air , there is no heat preservation device inside , the temperature can be adjusted , and the glue can reach the optimal sealing state , the double rubber wheel is used , the secondary gluing technology improves the complete sealing effect at the seal

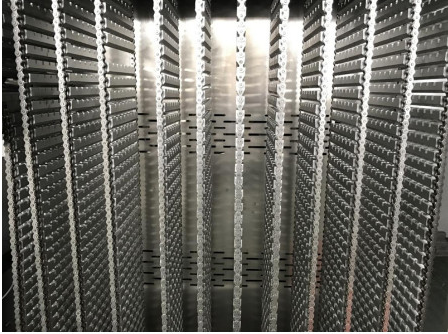

Free hanging drying template

After the sealing is completed , the capsule is introduced into the drying mold, during the air drying and solidification process, the capsule in the free hanging dry mold hole is always in a face-up sate to make a snake-shaped reciprocating motion, at the same time , it is easy to disassemble in terms of the need to change the mold specifications and cleaning

Capsule ejection device

There are 12 equal-limit ring in the finished product discharge bin , when the dry mold moves to the limit ring , there is a free hanging type to become a fixed-clamp type , so that each unit dry mold rotates 360 degrees , and the finished product is exported to in the discharge bin , plus 6 blowing pipes to prevent the finished product from remaining in the mold.

QC GUARANTEE

① all filling or capping machine from our factory ,QC personnel will carefully check the quality of the machine and do power-on test before the package leaves the warehouse.

②all filling or capping machine from our factory , There are special QC equipment to help QC personnel complete the inspection.

③all filling or capping machine from our factory ,QC stipulates that after each inspection, the quality inspection report must be filled in to ensure the quality of customers' goods.

AFTER-SALES SERVICE

① all filling or capping machine from our factory ,24hours*365days*60minutes online service. engineers, online sales, managers are always online .

② all filling or capping machine from our factory ,We have a complete set of after-sales service process.

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③all filling or capping machine from our factory , If there are quality or other problems with our products,our company's team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

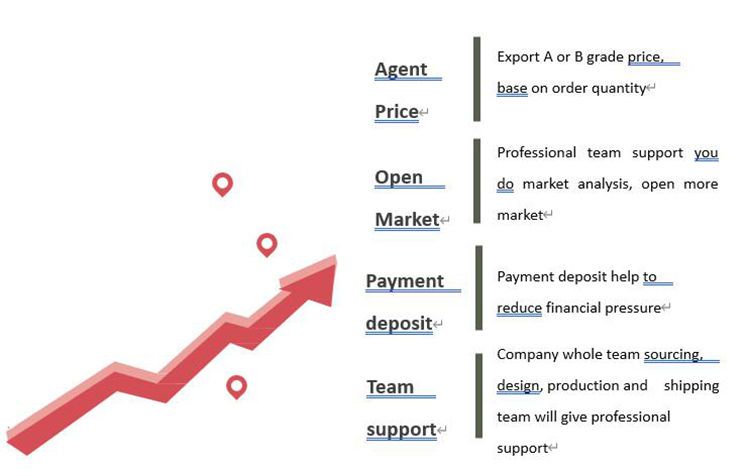

SPECIAL SERVICE FOR OUR AGENT

FAQ

1. Why choose us?

1.1- We have over 30 years experience on machinery making .

1.2- Our factory is located in Jiangsu province,more than 200 workers in our factory .

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit

our factory!

2.Can you customize machine ?

As a professional machinery manufacturer for more than 30 years,we have skilled OEM technique.

3. What about after sale service?

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video

or pictures. If the problem out of your control, we will arrange engineer to your factory.

4.How about warranty and spare parts?

We provide 1 year guarantee and enough spare parts for the machine,and most of the parts can be found in local market also,also you

can buy from us if all the parts that over than 1 year guarantee.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise

that our wooden packaging is strong enough and safety for long delivery .

6. What about the delivery time?

In stock machine:1-7days(depend on products).

MORE CUSTOMIZED FILLING MACHINE

FULL AUTO CAPSULE FILLING MACHINE

FULL AUTO CAPSULE FILLING MACHINE

Contact us know more filling machine for more type machine including semi auto filling machine,full auto filling machine , customized design filling system : filling machine , capping machine ,sealing machine , labeling machine ,packing machine