Good quality Aluminum Cap Sealing Machine - Semi Auto Vial Capping Machine for penicillin bottle – BRENU

Good quality Aluminum Cap Sealing Machine - Semi Auto Vial Capping Machine for penicillin bottle – BRENU Detail:

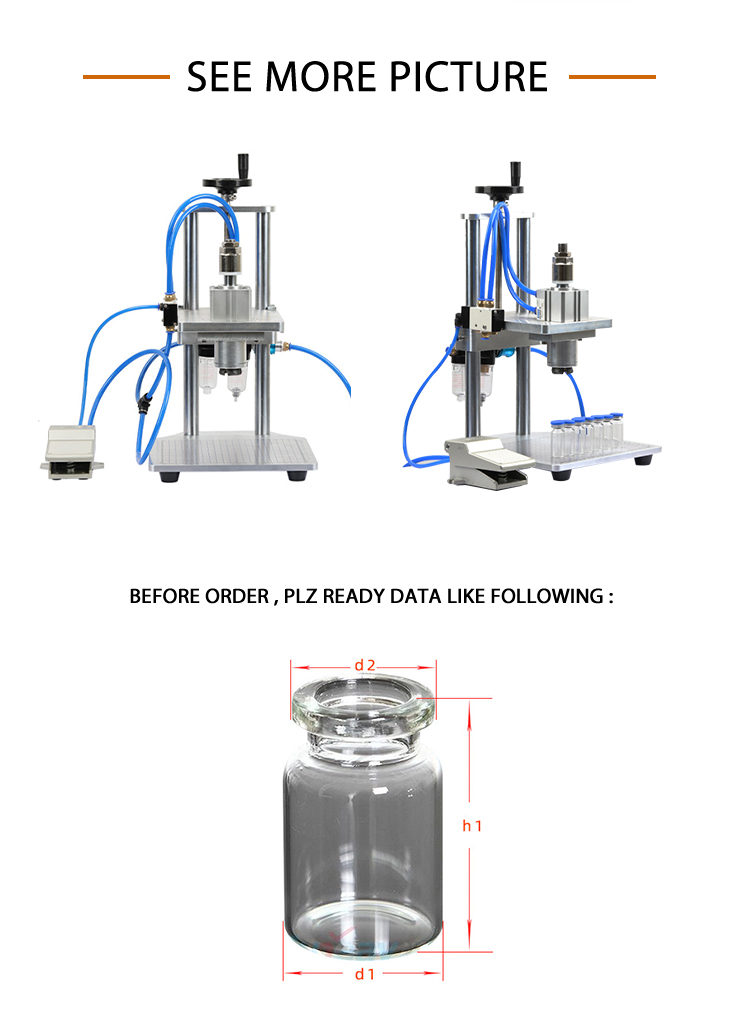

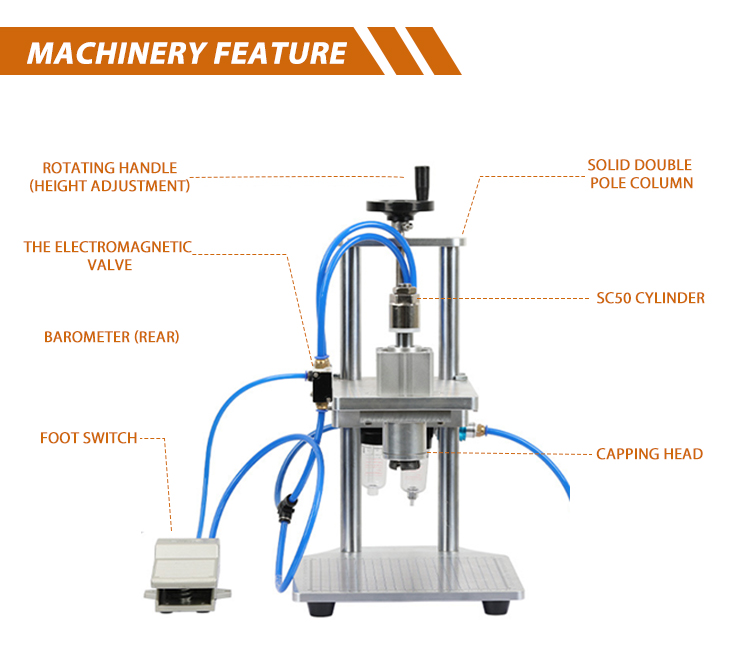

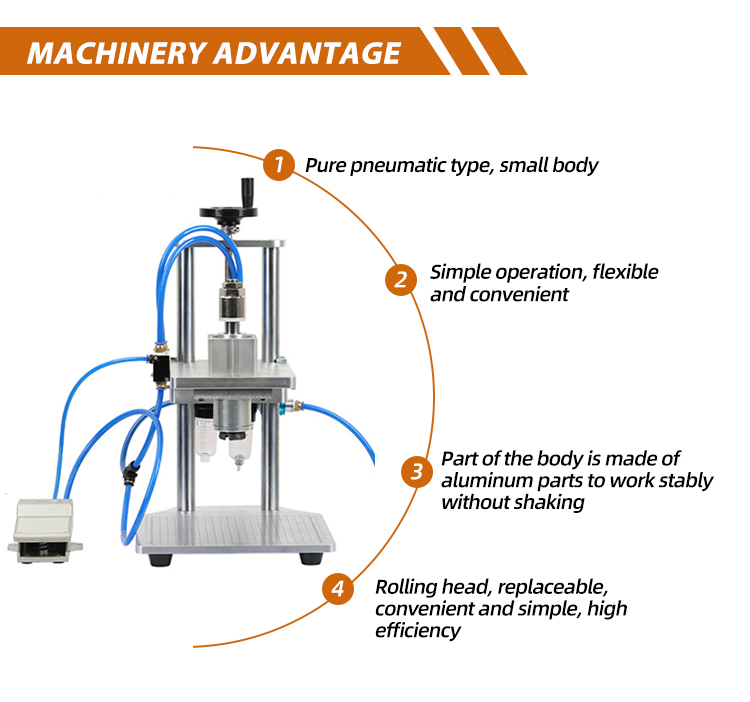

The vial bottle capping machine is a desktop three-knife cyclone capping machine with a stainless steel appearance and safe and convenient operation. When working, the capped bottle does not rotate, and the three cyclone knives are uniformly distributed at 120° to rotate the cap and seal. The handle is designed as a spring. The structure, the distance of the three knives can be fine-tuned, the adaptability is strong, and the capping yield is high. This machine is an ideal choice for troops, hospitals, laboratories, and small pharmaceutical factories.

| items | Technical | Detail |

| 1 | Air request | 0.5KPA |

| 2 | capacity | 10-50/min |

| 3 | The distance for lift | 27cm |

| 4 | Dimension | 415x370x555mm |

| 5 | Weight | 11kg |

Suitable for aluminum caps for oral liquid bottles, aluminum caps for 2 ml bottles, aluminum plastic caps for wife oral liquid bottles, aluminum caps for penicillin bottles, aluminum caps for spray tubes, and other rolling caps. It is the most ideal capping equipment for mass production in major hospitals, pharmaceutical factories, and scientific research in the country. The capping machine adopts electromagnetic oscillation to automatically arrange and feed caps, roll-type crimping and sealing, and pressure adjustment is convenient. Changing bottle specifications requires only a few parts to be changed to adapt to the crimping and sealing of bottles of different specifications. HSZ-12 single-pole multi-head capping machine can be used alone or directly equipped with a production line

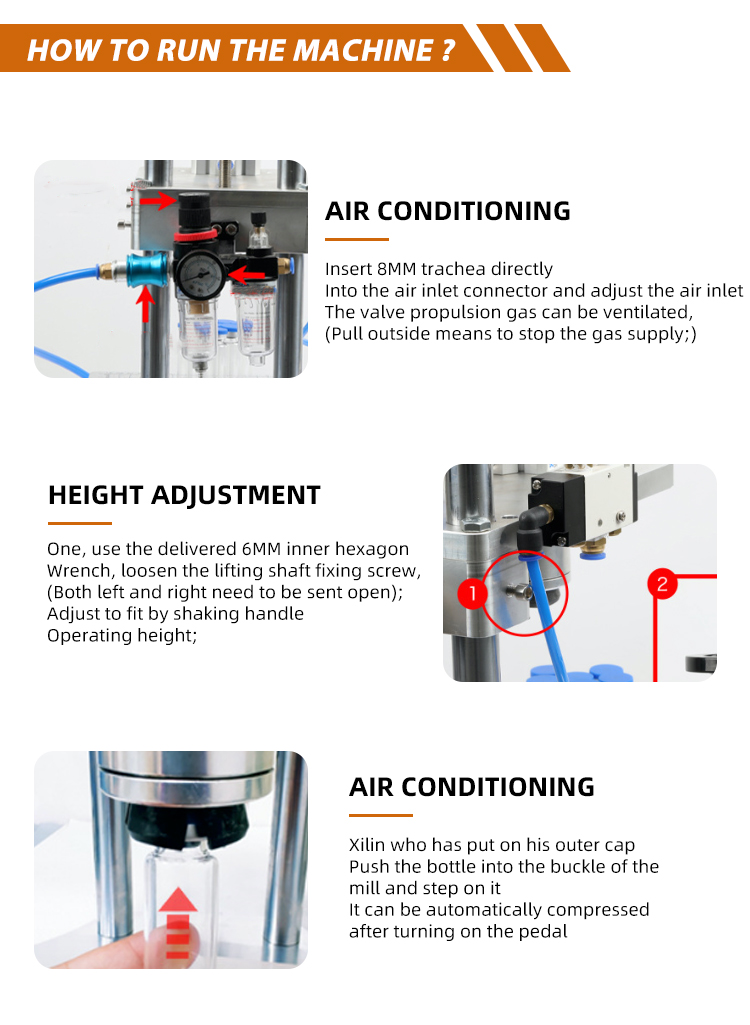

1. Put the bottle filled with liquid and capped on the lower tray, leaning on the V-shaped support block, holding the bottle with one hand, and pulling the handle backwards tightly with the other hand, then the tray is holding the bottle and lifting it upward Until the bottle cap is pressed tightly with the capping head.

2. After the bottle cap is pressed tightly with the capping head, the three continuously rotating capping cutter heads rotate several times to tighten the cap. (Note) The motor must run clockwise.

3. Push the handle forward to make the rolled lid return to the original position along with the tray. The whole operation process is completed. Repeat the above operation every time you roll a bottle cap.

Adjustment of the upper arm

This machine can be used for rolling 5-500ml bottle caps. When rolling bottles of different specifications, just put the bottle of this specification on the tray, hold the cross arm with one hand, and loosen the nut on the left side of the cross arm with the other hand to make the cross arm Lower or ascend until the capping head is about 20mm from the bottle cap, tighten the nut, and then use the included Allen wrench to close the support ring against the cross arm to lock the support ring. (Note) When tightening, pay attention to the alignment of the capping head and the cap.

Adjustment of V-shaped support block

Put the bottle into the lower V-shaped support, loosen the two screws on the support, move the bottle and the lower V-shaped block together, until the capping head is aligned with the bottle cap, then align the two on the V-shaped block. Tighten the screws.

Adjustment of capping head of semi-automatic electric capping machine

The machine is equipped with multiple capping heads, which can be selected according to the size of different bottle caps. Try it with a bottle before formal use.

1. The cap is not tightly rolled, you can unscrew the capping head lock nut and turn the capping head counterclockwise, and then lock the upper fixing nut.

2. The cap is rolled too tightly, and the cap is peeled off. Unscrew the upper capping head locking nut and screw into the upper capping head in a clockwise direction, and then lock the upper fixing nut.

3. The lower edge of the bottle cap is not tight, and the eccentricity of the three rolling heads can be appropriately adjusted according to the actual situation. If the tightening is too tight and the bottle is broken, the eccentricity of the three cutter heads can be adjusted appropriately

QC GUARANTEE

① all filling or capping machine from our factory ,QC personnel will carefully check the quality of the machine and do power-on test before the package leaves the warehouse.

②all filling or capping machine from our factory , There are special QC equipment to help QC personnel complete the inspection.

③all filling or capping machine from our factory ,QC stipulates that after each inspection, the quality inspection report must be filled in to ensure the quality of customers’ goods.

AFTER-SALES SERVICE

① all filling or capping machine from our factory ,24hours*365days*60minutes online service. engineers, online sales, managers are always online .

② all filling or capping machine from our factory ,We have a complete set of after-sales service process.

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③all filling or capping machine from our factory , If there are quality or other problems with our products,our company’s team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

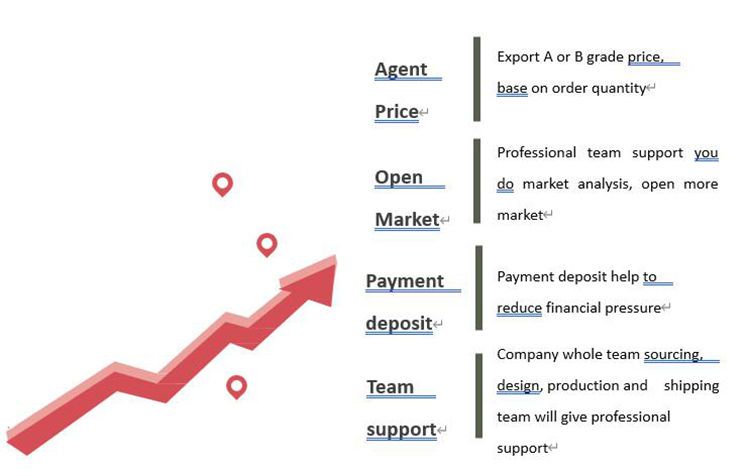

SPECIAL SERVICE FOR OUR AGENT

FAQ

1. Why choose us?

1.1- We have over 30 years experience on machinery making .

1.2- Our factory is located in Jiangsu province,more than 200 workers in our factory .

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit

our factory!

2.Can you customize machine ?

As a professional machinery manufacturer for more than 30 years,we have skilled OEM technique.

3. What about after sale service?

Engineer will go to buyer’s factory to install, test machines, and train buyer’s staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video

or pictures. If the problem out of your control, we will arrange engineer to your factory.

4.How about warranty and spare parts?

We provide 1 year guarantee and enough spare parts for the machine,and most of the parts can be found in local market also,also you

can buy from us if all the parts that over than 1 year guarantee.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise

that our wooden packaging is strong enough and safety for long delivery .

6. What about the delivery time?

In stock machine:1-7days(depend on products).

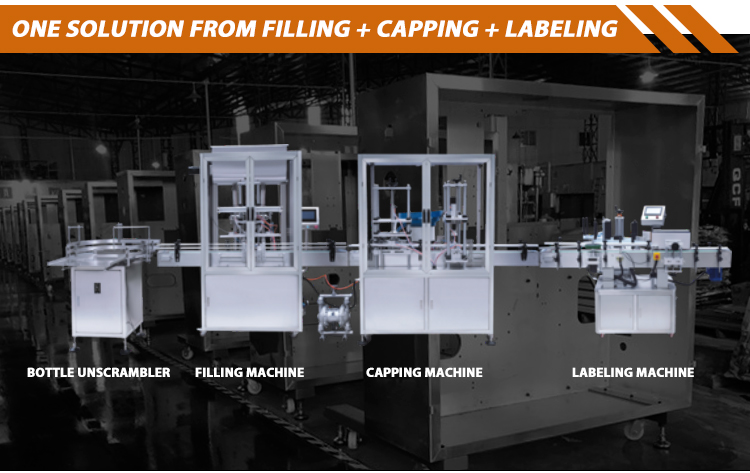

MORE CUSTOMIZED FILLING MACHINE

DIGITAL FILLING

AUTO FILLING

DIGITAL FILLING MACHINE

VACUUM HIGH PRECISION FILLING MACHINE

Contact us know more filling machine for more type machine including semi auto filling machine,full auto filling machine , customized design filling system : filling machine , capping machine ,sealing machine , labeling machine ,packing machine

Product detail pictures:

Related Product Guide:

That has a positive and progressive attitude to customer's interest, our organization consistently improves our products quality to satisfy the demands of shoppers and further focuses on safety, reliability, environmental specifications, and innovation of Good quality Aluminum Cap Sealing Machine - Semi Auto Vial Capping Machine for penicillin bottle – BRENU , The product will supply to all over the world, such as: Nepal, Finland, Slovak Republic, We will supply much better products with diversified designs and professional services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.