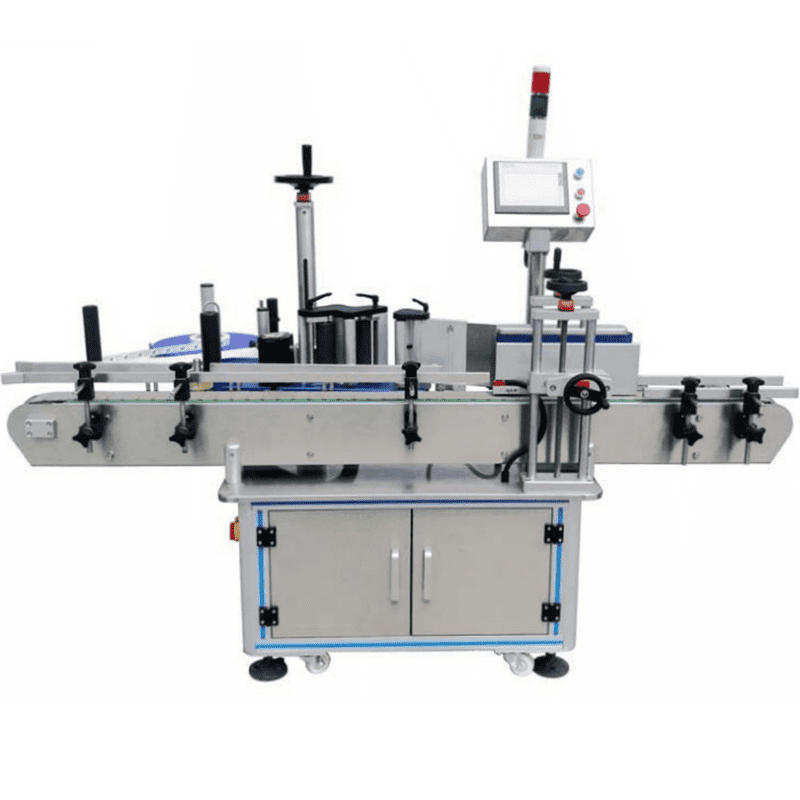

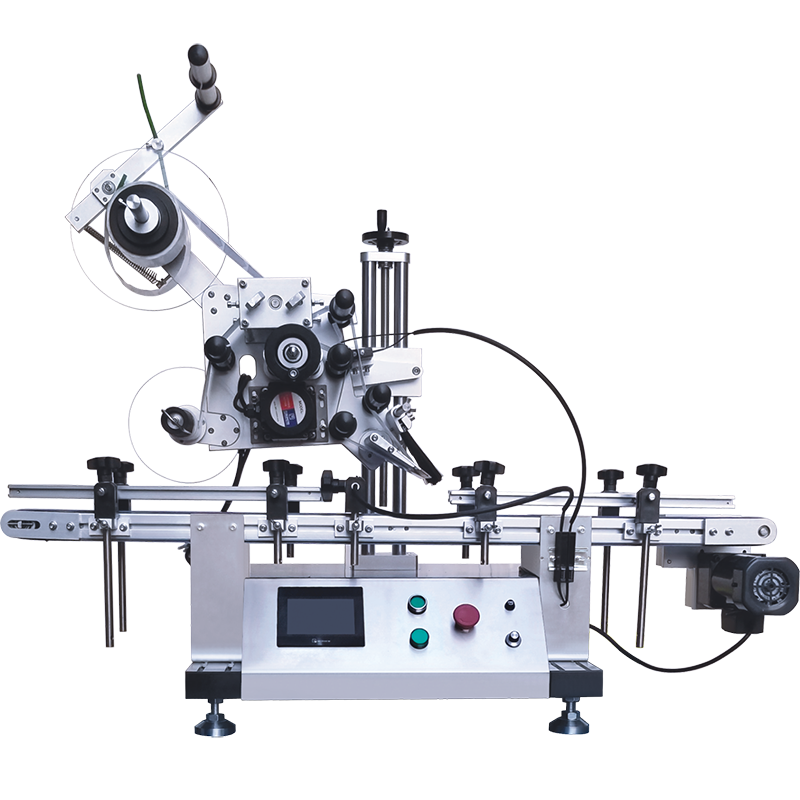

Full Auto Labeling Machine for round plate double face bottle label

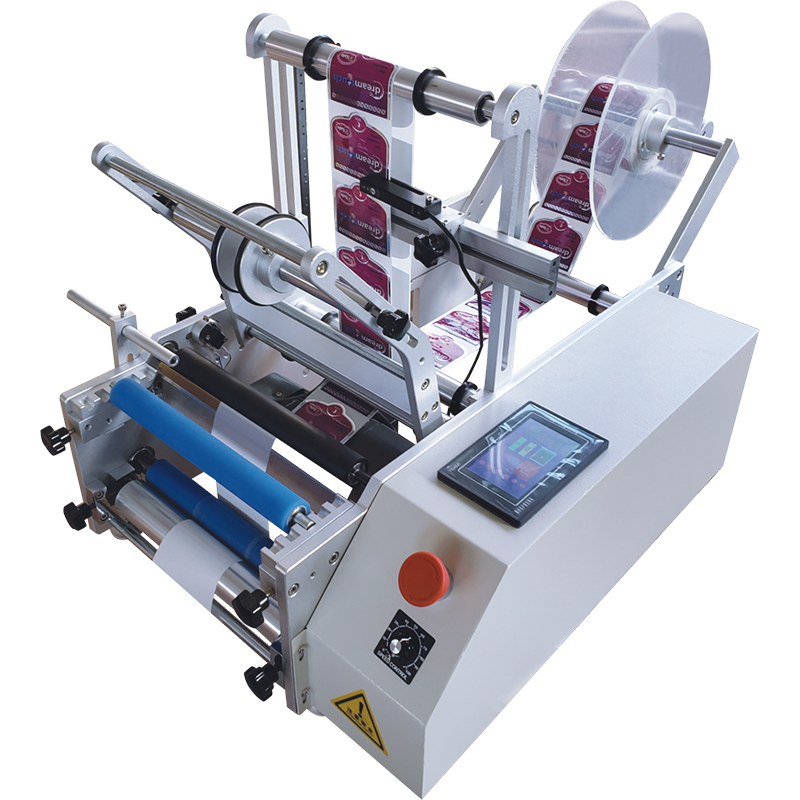

The automatic labeling machine is a machine that attaches the self-adhesive label to the surface of the package, and is an indispensable equipment for modern product packaging. The existing self-adhesive automatic labeling machine mainly adopts friction labeling method, which is characterized by fast labeling speed and high labeling accuracy.

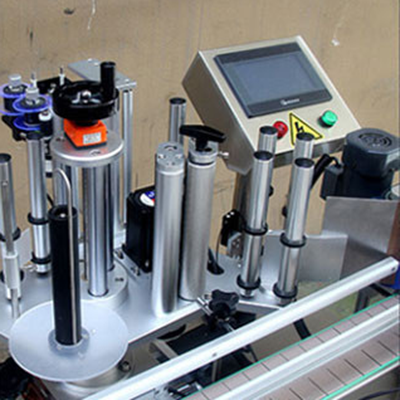

The automatic labeling machine is a necessary labeling equipment for labeling products. With the change of the labeled container and the material of the label, the automatic labeling machine can also label different products. Provides stronger labeling requirements. The automatic labeling machine mainly adopts advanced PLC intelligent system and micro-processing loop control system. The whole labeling process only needs one-key memory operation, the tank is automatically imported, and it is attached to the object according to the required position, and the label is cut and glued. It is a labeling equipment that automatically completes all processes such as positioning, attaching, pressing and heat shrinking and tightening of labels on the upper and lower sides of the tank. The automatic labeling machine control system uses electrical programming and full Chinese LCD touch screen, text type and button type, etc.

It is a modern mechanics packaging equipment with excellent and reliable working performance Widely used in food and beverage, pesticide chemical, paint and coating, medicine and health care and other industries.

The fully automatic vertical round bottle labeling machine ,can achieve automatic positioning labeling ,single standard ,double standard,label distance interval adjustment. This machine is suitable for PET bottles, metal bottles,glass bottles etc.It is widely used in food,beverage, cosmetic pharmaceutical industries.

|

Model |

BR-260 Labeling Machine |

|

Power supply |

AC220V 50Hz/60Hz 1.5KW |

|

Labeling capacity |

25- 50PCS /min(depends on bottle size) |

|

Labeling accuracy |

±1.0mm |

|

Suitable Bottle Diameter |

φ30-100mm |

|

Label size |

(L)15-200mm (H)15-150mm |

|

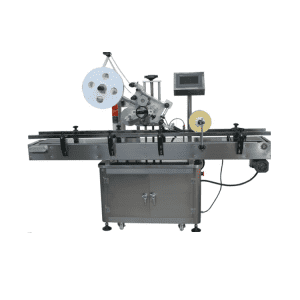

Roll inside diameter |

φ76mm |

|

Roll outside diameter |

φ350mm |

|

Conveyor Size |

1950(L)*100mm(W) |

|

Machine size |

About (L)2000*(W)1400*(H)1300(mm) |

|

Packing Size |

About 2120*940*1500mm |

|

Packing Weight |

About 220kgs |

Other Parts Show

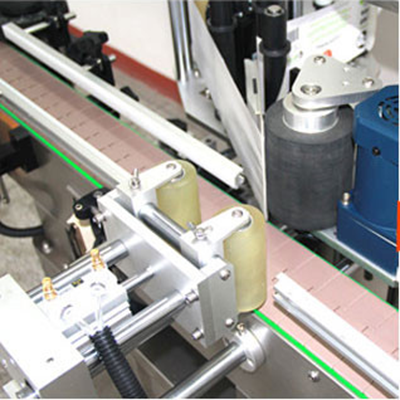

HIGH COINCIDENCE OF LABELS

The tape is deflected using a correction mechanism , the tape does not deviate , the labeling position can be adjusted in eight directions of X/Y/Z and right degrees of inclination, there is no dead angle adjustment

WIDE RANGE OF APPLICATION

It can be used for full-round labeling or half-circle labeling of round bottles , the labeling switching between bottles is simple and easy to adjust

EXCELLENT LABEL QUALITY

Equipped with a double labeling mechanism to ensure labeling accuracy for first and a second squeeze labeling to effectively eliminate air bubbles and ensure close contact between

INTELLIGENT CONTROL

Automatic photoelectric tracking, with function of no labeling , automatic calibration without label and automatic label detection function, to avoid missing label and label waste

QC GUARANTEE

① all filling or capping machine from our factory ,QC personnel will carefully check the quality of the machine and do power-on test before the package leaves the warehouse.

②all filling or capping machine from our factory , There are special QC equipment to help QC personnel complete the inspection.

③all filling or capping machine from our factory ,QC stipulates that after each inspection, the quality inspection report must be filled in to ensure the quality of customers' goods.

AFTER-SALES SERVICE

① all filling or capping machine from our factory ,24hours*365days*60minutes online service. engineers, online sales, managers are always online .

② all filling or capping machine from our factory ,We have a complete set of after-sales service process.

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③all filling or capping machine from our factory , If there are quality or other problems with our products,our company's team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

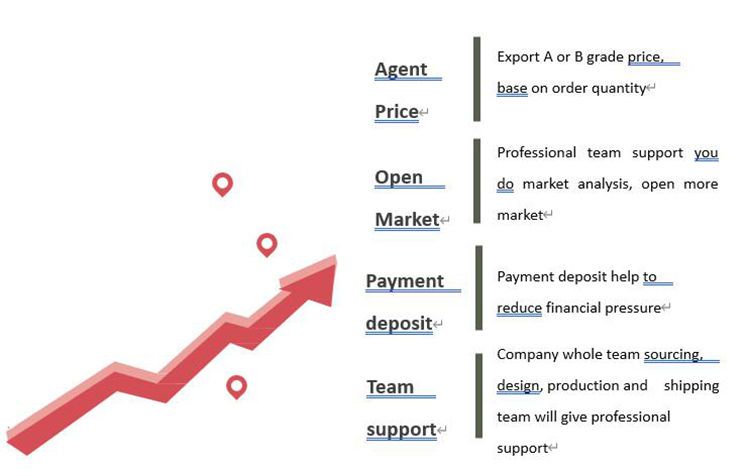

SPECIAL SERVICE FOR OUR AGENT

FAQ

1. Why choose us?

1.1- We have over 30 years experience on machinery making .

1.2- Our factory is located in Jiangsu province,more than 200 workers in our factory .

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit

our factory!

2.Can you customize machine ?

As a professional machinery manufacturer for more than 30 years,we have skilled OEM technique.

3. What about after sale service?

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video

or pictures. If the problem out of your control, we will arrange engineer to your factory.

4.How about warranty and spare parts?

We provide 1 year guarantee and enough spare parts for the machine,and most of the parts can be found in local market also,also you

can buy from us if all the parts that over than 1 year guarantee.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise

that our wooden packaging is strong enough and safety for long delivery .

6. What about the delivery time?

In stock machine:1-7days(depend on products).

MORE CUSTOMIZED FILLING MACHINE

Contact us know more filling machine for more type machine including semi auto filling machine,full auto filling machine , customized design filling system : filling machine , capping machine ,sealing machine , labeling machine ,packing machine