Full Auto Capsule Filling Machine For Powder

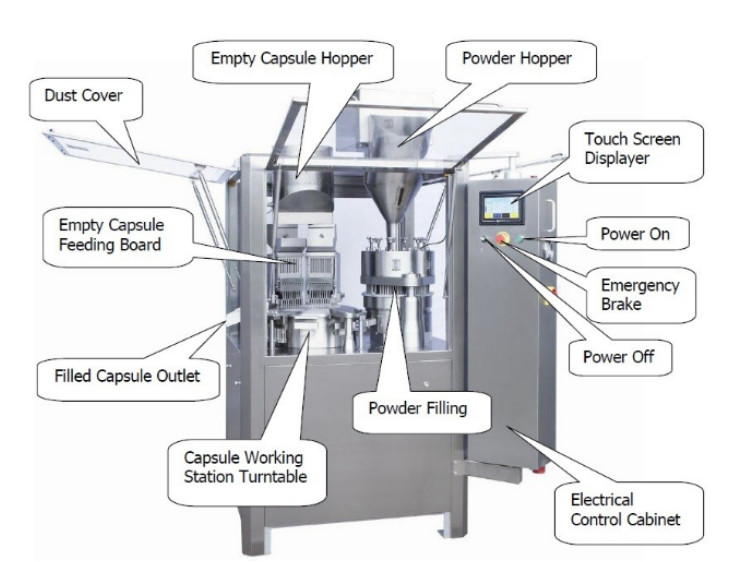

the capsule filling machine is an intermittent motion and hole plate type filling fully automatic capsule filling equipment. It adopts optimization design combined the characteristics of Chinese medicine and requirements of GMP, it has the characteristics of compact mechanism, small volume, lower noise, precision filling dosage, multi-function, running stably etc. It can finish the following motion at same time: capsule feeding, capsule separating, powder filling, capsule rejecting, capsule locking, finished capsule discharge and module cleaning etc. This machine is designed for meet the volume-produce on the basis of model NJP-1200 automatic capsule filling machine, it increase the lifting mechanism that easy to clean, it saves the cost and manpower for the enterprise that need volume-produce.

Main Features

1. It has been improved the inner design turret, and imports beeline bearings for each machine from Japan directly, so that it can be sure a longer usage-life and precision of machine.

2. The working station cam runs under the good lubricating condition, and maintains the inner lubrication of cam slot to a full extent, increasing the pressure pulverization oil pump, thus extends the operation life of the spare parts.

3. Single movement for both upper and lower segments with two-lip seal provide a much better sealing performance.

4. It is controlled by the computer, has a stepless timing with the frequency-conversion, the numberal showing makes an easy operation and clear appearance.

5. The multi-bore dosing brings a precision dosage (it is controlled around ±3.5%); The capsule qualified rate is higher than 99%. It can be filled with the Chinese traditional medicine and the Western medicine.

6. It has a protector equipment for the operator and the machine, it has an automatic pause equipment when it is lack for the material, It has steady and safe working, it is the best choice for the hard capsule made factories

the capsule filling machine is an intermittent motion and hole plate type filling fully automatic capsule filling equipment. It adopts optimization design combined the characteristics of Chinese medicine and requirements of GMP, it has the characteristics of compact mechanism, small volume, lower noise, precision filling dosage, multi-function, running stably etc. It can finish the following motion at same time: capsule feeding, capsule separating, powder filling, capsule rejecting, capsule locking, finished capsule discharge and module cleaning etc. This machine is designed for meet the volume-produce on the basis of model NJP-1200 automatic capsule filling machine, it increase the lifting mechanism that easy to clean, it saves the cost and manpower for the enterprise that need volume-produce.

|

Model |

NJP400 |

NJP600 |

NJP800 |

NJP1000 |

NJP1200 |

NJP2000 |

NJP2500 |

NJP3200 |

|

Capacity |

400BPM |

600BPM |

800BPM |

1000BPM |

1200BPM |

2000BPM |

2500BPM |

3200BPM |

|

Size of capsule |

capsule size #000-#5 and safety capsule A-E |

|||||||

|

Total power |

3.7kw |

4.9kw |

4.9kw |

5.75KW |

5.75KW |

6.45kw |

6.45kw |

9.55kw |

|

Water supply |

500L/H,0.2-0.1Mpa |

|||||||

|

Dust collector |

160m3/h |

|||||||

|

Overall dimensions (mm) |

720*680*1700 |

930*790*1930 |

930*790*1930 |

1020*860*1970 |

1020*860*1970 |

1000*1050*1950 |

1000*1050*1950 |

1130*1280*2060 |

|

Weight |

700kg |

800kg |

800kg |

900kg |

900kg |

1500kg |

1500kg |

2400kg |

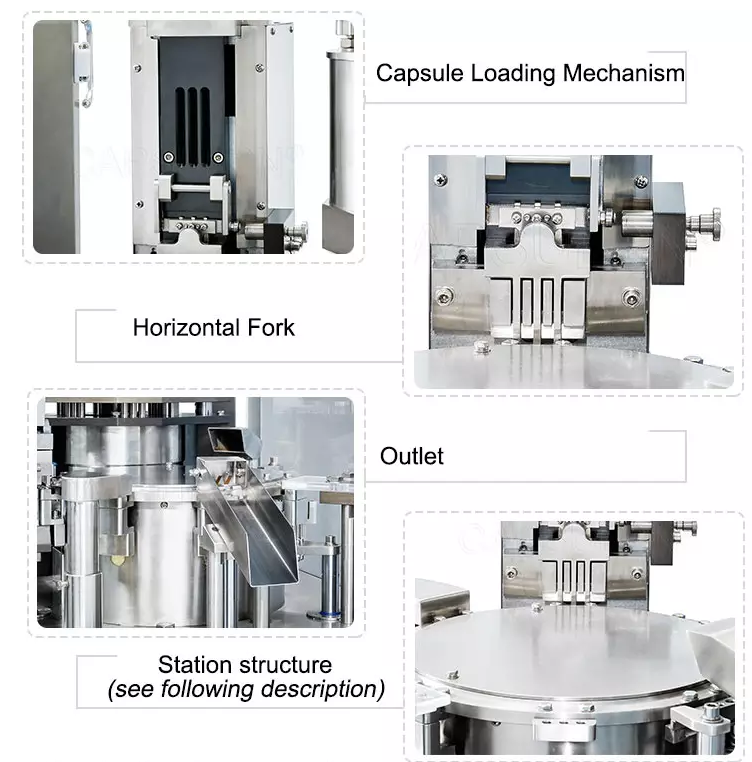

our powder capsule filling machine with PLC control system , Turret ,with segments to hold the capsules , machine structure , with connections for product and ventilation , the electrical unit provides the machine with enough powder that it requires for most of its operations

Special from our powder capsule filling machine

1. capsule orientation and separation

2. Reserved work position

3. Free for an optional pellet or tablet station

4. Dosing station for powder, pellets

5. Free for an optional pellet or tablet station

6. Faulty capsule rejection

7. Reserved work position

8. Capsule closing

9. Qualified capsule ejection

10. Segment cleaning with compressed air

QC GUARANTEE

① all filling or capping machine from our factory ,QC personnel will carefully check the quality of the machine and do power-on test before the package leaves the warehouse.

②all filling or capping machine from our factory , There are special QC equipment to help QC personnel complete the inspection.

③all filling or capping machine from our factory ,QC stipulates that after each inspection, the quality inspection report must be filled in to ensure the quality of customers' goods.

AFTER-SALES SERVICE

① all filling or capping machine from our factory ,24hours*365days*60minutes online service. engineers, online sales, managers are always online .

② all filling or capping machine from our factory ,We have a complete set of after-sales service process.

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③all filling or capping machine from our factory , If there are quality or other problems with our products,our company's team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

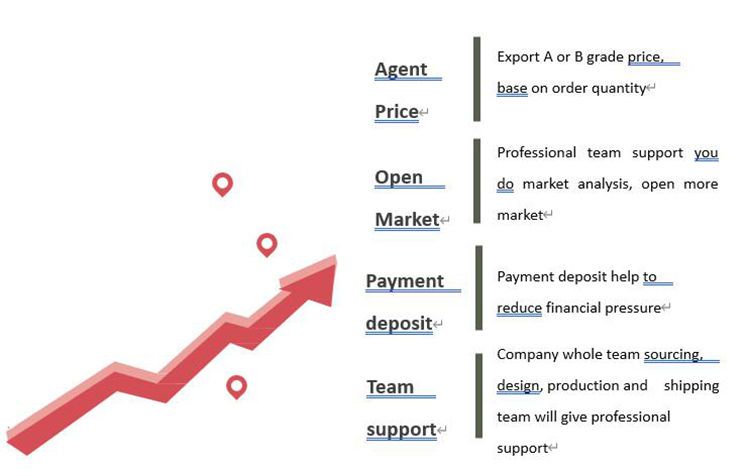

SPECIAL SERVICE FOR OUR AGENT

FAQ

1. Why choose us?

1.1- We have over 30 years experience on machinery making .

1.2- Our factory is located in Jiangsu province,more than 200 workers in our factory .

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit

our factory!

2.Can you customize machine ?

As a professional machinery manufacturer for more than 30 years,we have skilled OEM technique.

3. What about after sale service?

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video

or pictures. If the problem out of your control, we will arrange engineer to your factory.

4.How about warranty and spare parts?

We provide 1 year guarantee and enough spare parts for the machine,and most of the parts can be found in local market also,also you

can buy from us if all the parts that over than 1 year guarantee.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise

that our wooden packaging is strong enough and safety for long delivery .

6. What about the delivery time?

In stock machine:1-7days(depend on products).

MORE CUSTOMIZED FILLING MACHINE

FULL AUTO CAPSULE FILLING MACHINE

SEMI AUTO CAPSULE FILLING MACHINE

Contact us know more filling machine for more type machine including semi auto filling machine,full auto filling machine , customized design filling system : filling machine , capping machine ,sealing machine , labeling machine ,packing machine