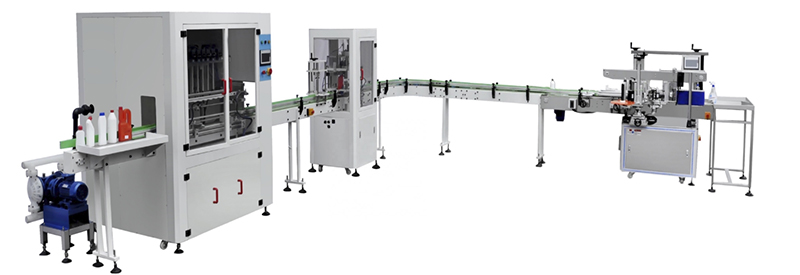

Filling capping labeling machine

The olive oil filling production line is very new off the assembly line. It is an upgrade model based on the original liquid filling production line of our company. It not only upgrades the filling accuracy and product appearance layout, but also improves the performance, stability, and quality of the product. The applicability of different materials of the product has also been comprehensively upgraded to make the product more competitive in the market. It is suitable for the packaging of olive oil, sesame oil, peanut oil, blended oil, soy sauce and other products. The olive oil filling production line consists of a 4-head automatic filling machine, an automatic capping machine, and a round bottle (flat) labeling machine. The new model has more stable performance, low failure rate and high technology content.

A. PLC control, frequency conversion speed regulation, high degree of automation;

b. It adopts self-flow filling, which is suitable for various liquids with good flow performance and high precision; the structure of the pump adopts a quick-connect dis-assembly mechanism, which is convenient for cleaning and disinfection.

c. No bottle no filling, with automatic counting function.

d. The whole machine is designed in accordance with GMP requirements, all the parts in contact with liquid are made of excellent stainless steel, and the surface has been polished, with a beautiful and generous appearance;

e. Strong applicability, can be applied to bottles of different specifications, easy to adjust, and can be completed in a short time.

A. Bottle Unscrambler

| 1 |

Model |

800/1000 |

| 2 |

Turntable diameter |

800mm/1000mm |

| 3 |

Suitable Bottle Diameter |

20-100mm |

| 4 |

Suitable Bottle Height |

30-120mm |

| 5 |

Working Speed |

About 40-60 bottles/min(depends on bottle size) |

| 6 |

Motor Power |

2000W |

| 7 |

Power Supply |

220V/50-60HZ |

| 8 |

Net weight |

About 109.5kg /135kg |

| 9 |

Gross weight |

About 155kg/180kg |

| 10 |

Package size |

About 1150*1000* 1320mm/1350*1315*1235mm |

B. Full Automatic Filling Machine

| 1 |

Container size |

φ20-160mm H30-300mm |

||

| 2 |

Max flow rate |

5500ml/min |

5500ml/min |

7500ml/min |

| 3 |

Material of pump |

304stainless steel |

316stainless steel |

316stainless steel |

| 4 |

Filling accuracy |

≤100ml deviation≤±1ml > 100ml deviation≤±1% ( based on water) |

||

| 5 |

Filling speed |

20-50pcs/min |

20-50pcs/min |

25-60pcs/min |

| 6 |

|

(depending on bottles and flling liquid) |

||

| 7 |

Power supply |

220V-50HZ/110V-60HZ |

||

| 8 |

The whole machine power |

2000W |

||

| 9 |

Packing weight |

About 150kg |

||

| 10 |

Packing size |

About 2000*820*1580mm |

||

| 11 |

Size of air compressor connector |

OD8mm |

||

C. Full Automatic Capping Machine

| 1 |

Bottle height |

30-300mm |

| 2 |

Bottle diameter |

18-70mm |

| 3 |

Working speed |

20-60 bottles / minute (depending on bottle and cap size and shape) |

| 4 |

Working voltage |

AC220V/110V 50-60HZ |

| 5 |

Working pressure |

0.4-0.6 MPa |

| 6 |

Dimension |

About 1930*740*1600mm |

| 7 |

Package size |

About 2000*820*1760mm |

| 8 |

Net weight |

About 113kg |

| 9 |

Gross weight |

About 192.5kg |

| 10 |

Bottle height |

30-300mm |

D. Full Automatic Labeling Machine

| 1 |

Labeling capacity |

25-50PCS /min(depends on bottle size) |

| 2 |

Labeling accuracy |

±1mm |

| 3 |

Bottle Diameter |

φ30- 100mm |

| 4 |

Label size |

(L)15-200mm (H)15-150mm |

| 5 |

Roll inside |

φ76mm |

| 6 |

Roll outside diameter |

φ350mm |

| 7 |

Power supply |

AC220V 50Hz/60Hz 1500W |

| 8 |

Package Size |

About 2110*1040*1400mm |

| 9 |

Net weight |

About 223.5kg |

| 10 |

Gross weight |

About 280kg |

MORE CASE SHOW