Factory Price For China Multi-Function Automatic Vertical Pouch Packing Machine for Food Sugar Snack Chips Packaging Bag Bagger

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Factory Price For China Multi-Function Automatic Vertical Pouch Packing Machine for Food Sugar Snack Chips Packaging Bag Bagger, Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for China Bag Packing Machine, Small Bag Packing Machine, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

The grain mill is a continuous feeding operation, with luxurious and generous structure, low noise, fine milling, no dust, and simple and convenient operation. It is suitable for on-site processing of various grains and Chinese medicinal materials in supermarkets, shopping malls and store stalls.

Mixer :The mixer is suitable for mixing powder or granular materials in the chemical, food, pharmaceutical, feed, ceramic, metallurgical and other industries.

multi-function packing machine , here show professional for the powder , from rough to fine or super powder pouch bag filling and sealing , the process starts with a cylindrical roll of film, the vertical bagging machine will transfer film from the roll and thru the forming collar (sometimes referred to as tube or plow). Once transferred thru the collar the film will then fold where upon the vertical seal bars will extend and seal the back of the pouch. Once the desired pouch length is transferred it is filled with product. Once filled the horizontal seal bars will then close, seal and cut the pouch providing a finished product that includes a bag with top/bottom horizontal seals and one vertical back seal.this machine as the bag filler including all industries like snack food , coffee , powders , frozen food , candy , chocolates , tea ,sea food and more

A. Grain Mill

The grain mill is a continuous feeding operation, with luxurious and generous structure, low noise, fine milling, no dust, and simple and convenient operation. It is suitable for on-site processing of various grains and Chinese medicinal materials in supermarkets, shopping malls and store stalls.

| 1 | Name | High speed grind mill |

| 2 | Model | BL-3500 |

| 3 | speed | 2840r/min |

| 4 | power | 3.5kw |

| 5 | Input power | 220v/50HZ |

| 6 | Capacity | 80-120KG/H |

| 7 | Grind size | 60-200mesh |

| 8 | Weight | 52kg |

| 9 | Machinery size | 610x310x680mm |

| 10 | Material | Food grade stainless steel |

B. MIX

Mixer :The mixer is suitable for mixing powder or granular materials in the chemical, food, pharmaceutical, feed, ceramic, metallurgical and other industries.

|

Model |

Tank space (L) |

Max Loading space (L) |

Max loading weight (KG) |

Speed (R/MIN) |

Power (KW) |

Size (MM) |

Weight (KG) |

|

BRN-50 |

50 |

40 |

25 |

0-20 |

1.1 |

1150x1400x1300 |

300 |

|

BRN-100 |

100 |

80 |

50 |

0-20 |

1.5 |

1250x1800x1550 |

800 |

|

BRN-200 |

200 |

160 |

100 |

0-15 |

2.2 |

1450x2000x1550 |

1200 |

|

BRN-400 |

400 |

320 |

200 |

0-15 |

4 |

1650x2200x1550 |

1300 |

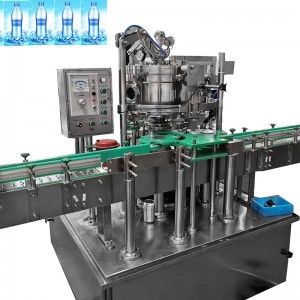

C. Power Packing Machine

multi-function packing machine , here show professional for the powder , from rough to fine or super powder pouch bag filling and sealing , the process starts with a cylindrical roll of film, the vertical bagging machine will transfer film from the roll and thru the forming collar (sometimes referred to as tube or plow). Once transferred thru the collar the film will then fold where upon the vertical seal bars will extend and seal the back of the pouch. Once the desired pouch length is transferred it is filled with product. Once filled the horizontal seal bars will then close, seal and cut the pouch providing a finished product that includes a bag with top/bottom horizontal seals and one vertical back seal.this machine as the bag filler including all industries like snack food , coffee , powders , frozen food , candy , chocolates , tea ,sea food and more

|

1 |

Technical Specification |

Descriptions |

|

2 |

Capacity |

30-70 bags/min (determined by powder fluidity and the film) |

|

3 |

Sealing Type |

3-Side Sealing |

|

4 |

Sealing Method |

Heat Sealing |

|

5 |

Filling Range |

2-100 g |

|

6 |

Film Width |

50-280 mm |

|

7 |

Finished Bag Size |

W 25~140mm; L 30~180 mm |

|

8 |

Filling System |

Screw Conveyor |

|

9 |

Voltage |

220V; 50HZ; 1.9KW |

|

10 |

Driven Type |

Electric (and Pneumatic if seal round corner bag) |

|

11 |

Controller Screen |

WIENVIEW |

|

12 |

PLC System |

Mitsubishi |

|

13 |

Size and Weight |

L 950 x W 700 x H 1030 mm; 280 kg |

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Factory Price For China Multi-Function Automatic Vertical Pouch Packing Machine for Food Sugar Snack Chips Packaging Bag Bagger, Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

Factory Price For China Bag Packing Machine, Small Bag Packing Machine, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.