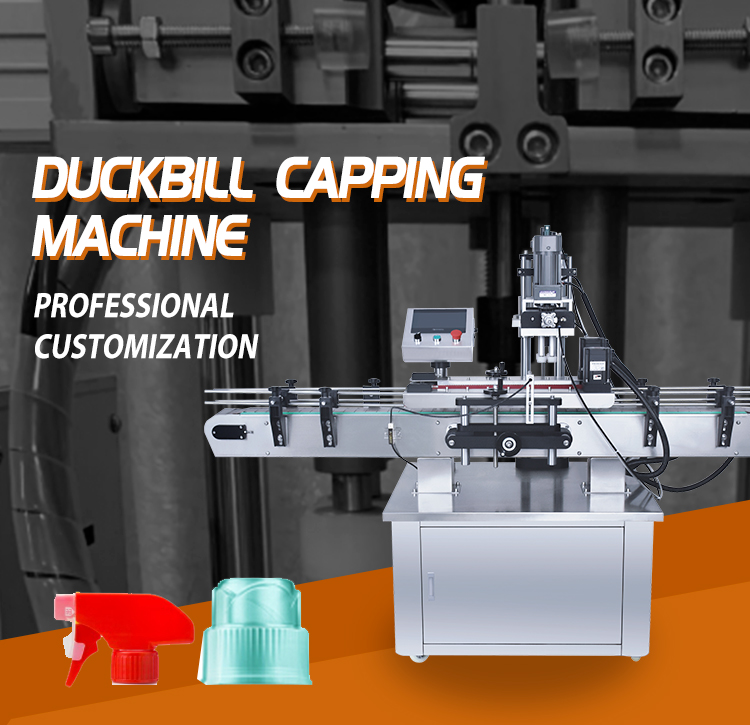

Auto Capping Machine For Rotary Cap Plastic Metal

There are two kinds of capping machines, one is a linear capping machine and the other is a rotary capping machine, here we introduce the linear capping machine

The functional structure of the capping machine includes automatic capping, capping, and automatic capping. It has the characteristics of fast production speed, high degree of automation, and stable operation; it can be widely used in food, medicine, chemical industry and other fields.

It is suitable for capping and capping of bottles of different materials and specifications, suitable for screw caps, anti-theft caps, child-proof caps, pressure caps, etc. Equipped with constant torque capping head, the pressure can be easily adjusted. The structure is compact and reasonable, and it can be easily linked with other equipment to form a line.

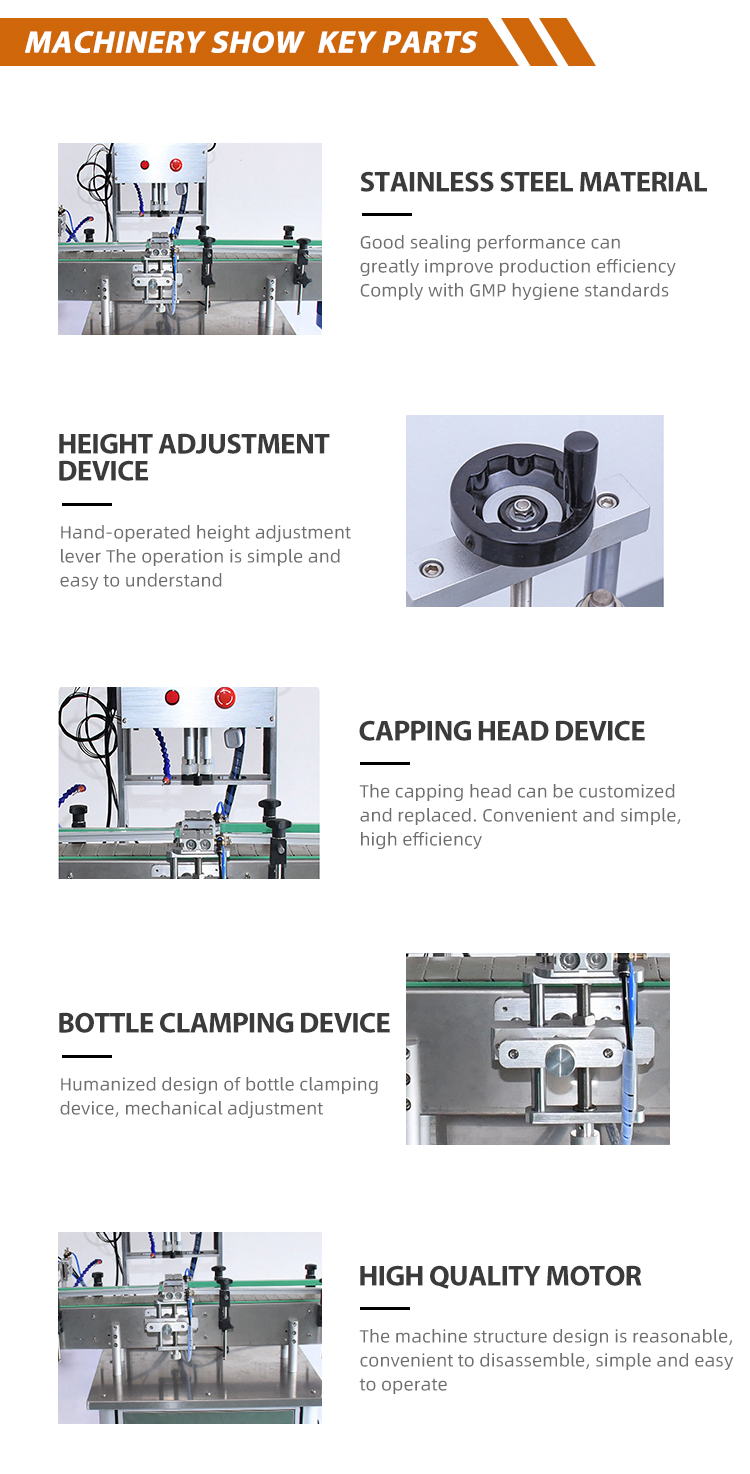

Advantages of the machine: Linear design, convenient and beautiful to form an assembly line.

The speed of the host adopts imported frequency converter, which can carry out step less speed regulation and automatic counting.

The strong electromagnetic left-hand cap torque is used, which completely solves the drawbacks of the traditional mechanical friction plate when the cap is tightened and loosened.

There are two kinds of capping machines, one is a linear capping machine and the other is a rotary capping machine, here we introduce the linear capping machine

The functional structure of the capping machine includes automatic capping, capping, and automatic capping. It has the characteristics of fast production speed, high degree of automation, and stable operation; it can be widely used in food, medicine, chemical industry and other fields.

It is suitable for capping and capping of bottles of different materials and specifications, suitable for screw caps, anti-theft caps, child-proof caps, pressure caps, etc. Equipped with constant torque capping head, the pressure can be easily adjusted. The structure is compact and reasonable, and it can be easily linked with other equipment to form a line.

Advantages of the machine: Linear design, convenient and beautiful to form an assembly line.

The speed of the host adopts imported frequency converter, which can carry out step less speed regulation and automatic counting.

The strong electromagnetic left-hand cap torque is used, which completely solves the drawbacks of the traditional mechanical friction plate when the cap is tightened and loosened.

TECHNICAL PARAMETERS

|

items |

Technical |

Detail |

|

0 |

Model |

BLT |

|

1 |

Main power |

0.8kw |

|

2 |

Air request |

0.4-0.6MPA |

|

3 |

capacity |

30-60pcs/min (depending on bottle and caps) |

|

4 |

Working voltage |

AC220V/110V 50-60HZ 1.9KW |

|

5 |

Dimension |

4000x1400x2000mm |

|

6 |

Weight |

300kg |

QC GUARANTEE

① all filling or capping machine from our factory ,QC personnel will carefully check the quality of the machine and do power-on test before the package leaves the warehouse.

②all filling or capping machine from our factory , There are special QC equipment to help QC personnel complete the inspection.

③all filling or capping machine from our factory ,QC stipulates that after each inspection, the quality inspection report must be filled in to ensure the quality of customers' goods.

AFTER-SALES SERVICE

① all filling or capping machine from our factory ,24hours*365days*60minutes online service. engineers, online sales, managers are always online .

② all filling or capping machine from our factory ,We have a complete set of after-sales service process.

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③all filling or capping machine from our factory , If there are quality or other problems with our products,our company's team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

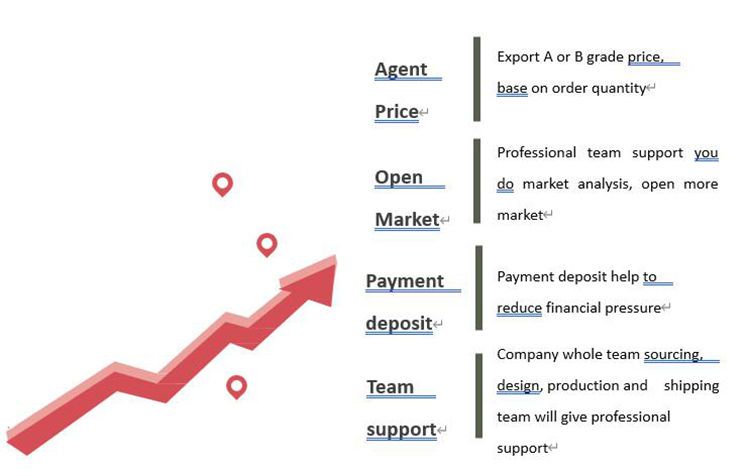

SPECIAL SERVICE FOR OUR AGENT

FAQ

1. Why choose us?

1.1- We have over 30 years experience on machinery making .

1.2- Our factory is located in Jiangsu province,more than 200 workers in our factory .

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit

our factory!

2.Can you customize machine ?

As a professional machinery manufacturer for more than 30 years,we have skilled OEM technique.

3. What about after sale service?

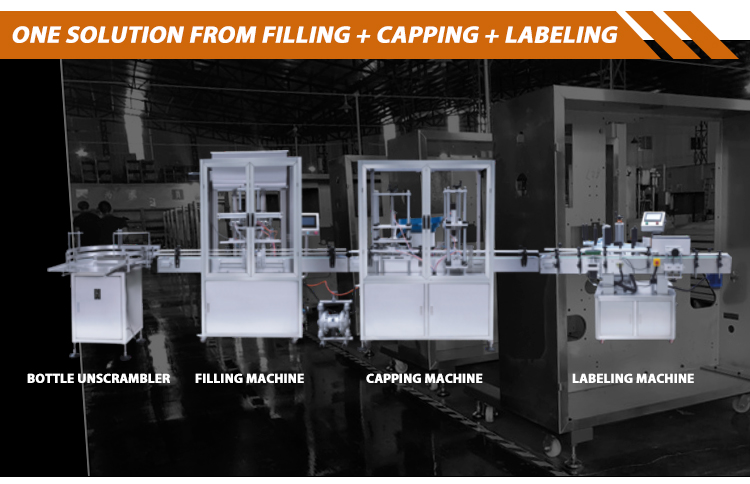

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video

or pictures. If the problem out of your control, we will arrange engineer to your factory.

4.How about warranty and spare parts?

We provide 1 year guarantee and enough spare parts for the machine,and most of the parts can be found in local market also,also you

can buy from us if all the parts that over than 1 year guarantee.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise

that our wooden packaging is strong enough and safety for long delivery .

6. What about the delivery time?

In stock machine:1-7days(depend on products).