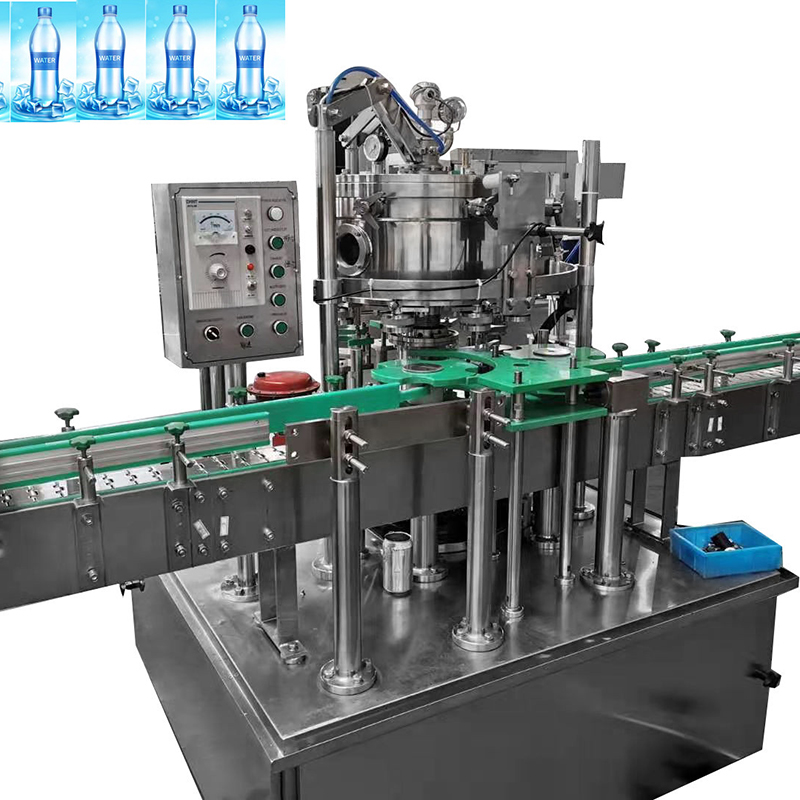

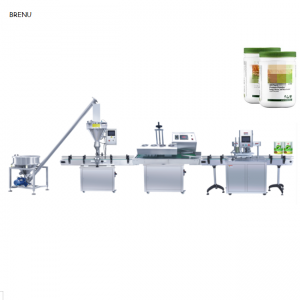

Pet Water Bottle Filling Machine (Water Tea Oil Without Carbonate)

Bottled water filling machines are mainly used for filling water and beverages. At present, most bottled water filling machines combine functions such as flushing, filling, and capping into one body, and the whole process is automated. It is used in pet, plastic Bottle filling juice, mineral water, pure water, plus temperature control device can also be hot filling. The three-in-one full-bottle filling machine adopts advanced PLC control, frequency conversion speed regulation, and stable operation. Taking into account the convenience of customers, RRENU recommend the water treatment equipment together, so that customers can achieve one-stop procurement.

A.WATER TREATMENT

B.WATER MACHINE (WASHING, FILLING ,CAPPING ,LABEL SHRINK MACHINE )

MACHINERY DETAIL SHOW

A.WATER TREATMENT

Water tank

| 1 | Water Tank material | Stainless steel 304# |

| 2 | Thickness | 1mm |

| 3 | Capacity | 2000L |

Quartz sand filtration

| 1 | Filter material | Multi-layer filter material is used to remove materials with a particle size of 20 microns or more, such as sand, rust, colloidal substances, and suspended substances contained in the raw water. |

| 2 | Capacity | 2ton/h |

| 3 | Tank size | Diameter 320mm , height 2200mm |

| 4 | Tank Material | Stainless steel 304# |

| 5 | Water quality | The effluent water quality should meet the national drinking water quality standards |

Carbon filter

| 1 | Filter material 1 | Coconut/husk activated carbon is used, which has the function of high-efficiency adsorption, which greatly improves the purification degree of the produced water. It has significant removal performance for different leaves, organic matter, color, colloid, iron and residual chlorine in the water. |

| 2 | Special material | Using cation exchange resin, the resin is used to absorb calcium and magnesium ions in water to prevent them from crystallizing out at the end of the reverse osmosis membrane |

| 3 | Capacity | 2ton/h |

| 4 | Tank size | Diameter 320mm, height 2200mm |

| 5 | Tank material | Stainless steel 304# |

| 6 | Water quality | The effluent water quality should meet the national drinking water quality standards |

high precision filter

The precision filter is a micro porous membrane made of high-tech and polymer materials as the filter medium. It is one of the effective means to solve the problem of substance separation. It is a modern advanced precision equipment. It has high filtration efficiency, good quality, and operation. It has the advantages of simplicity and low production cost. It is an updated product of the plate and frame filter. It has a wide range of applications and is an indispensable fine filter equipment in the medicine, beverage, electronics, chemical, water treatment and other industries.

| 1 | Tank size | Diameter 280mm, height 1100mm |

| 2 | Filter precision | 0.45um |

| 3 | Working pressure | 0.2Mpa |

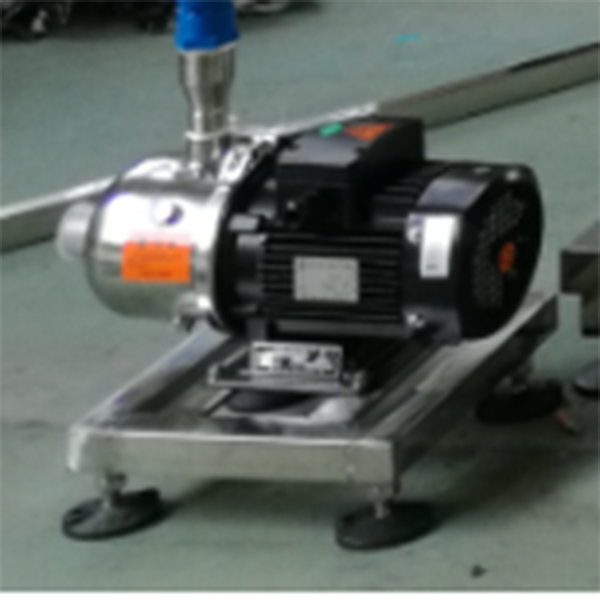

RO system

The core component of the device is the southern pump, which has simple structure, convenient operation and high technical level. Under the condition that the conductivity of the raw water is less than 250us/cm, the water quality index of the water treated by this device can reach 100% of the national pure water. The product is currently the most advanced pure water treatment equipment。

| 1 | Material | Stainless steel 304# |

| 2 | Mold cover | Stainless steel 304# |

| 3 | Filter film | Imported |

| 4 | Pipe fitting valve | Stainless steel 304# |

| 5 | Salt rejection percent | 98% |

| 6 | Recovery | 50-60% |

ozone(air ,oxygen,double type cooling ,heat dissipation, protect once over heating )

B.WATER MACHINE (WASHING, FILLING ,CAPPING ,LABEL SHRINK MACHINE )

BQS-12 WASHING MACHINE

| No | Parts name | Detail | Remark |

| 1 | Washing head | 12 pcs | |

| 2 | Capacity | 1000-4000BPH | 500ML ,speed adjustable |

| 3 | Power | 0.75kw | |

| 4 | Machinery size | 1200x1120x1800mm | |

| 5 | Machinery weight | 550kg | |

| 6 | Water pump | International brand pump | |

| 7 | Operate panel | Button type |

BCYG-12 filling machine (special for plastic bottle , Mineral water, pure water filling)

| No | Parts name | Detail | Remark |

| 1 | Filling head | 12 pcs | |

| 2 | Capacity | 1000-2000BPH | 500ML ,speed adjustable |

| 3 | Power | 0.75kw | |

| 4 | Machinery size | 1200x1120x1800mm | |

| 5 | Machinery weight | 550kg | |

| 6 | Material for touch water | 304# stainless steel | |

| 7 | Motor | China international brand | |

| 8 | Operate panel | Button type |

BFXZ-1CAPPING MACHINE (SINGLE ) for plastic bottle and cap

| No | Parts name | Detail | Remark |

| 1 | Cap head | 1 pcs | |

| 2 | Capacity | 1500-2000BPH | 500ML ,speed adjustable |

| 3 | Power | 0.75kw | |

| 4 | Machinery size | 900x700x1900mm | |

| 5 | Machinery weight | 350kg |

SHRINK TUNNEL BY STEAM

The steam ejection method adopts the design of a steam drum, and the steam diversion system can be adjusted. The pipeline is smooth and does not occupy space. Each side of the ejection outlet is divided into three sections. The height, front and rear, and air output of each section can be adjusted separately to achieve the shrinkage effect. Realm.

The low-pressure sub-steam drum is designed with seamless steel pipes, and each connecting pipe uses stainless steel hose quick couplings, which is convenient for disassembly and installation.

The whole machine shell is made of stainless steel SUS304, which saves energy and complies with food safety standards.

The stainless steel drain pan at the bottom concentrates the condensed water, which can be taken over and drained, and the working environment is not affected. The box body has two windows at the front and the back.

The whole machine adopts waterproof design and is made of stainless steel, which is convenient for operation and maintenance.

| 1 | Size | L1800XW450XH1600mm |

| 2 | Weight | 300kg |

STEAM GENERATOR

Thickened boiler steel inner tank, high-performance heating pipe, instrument valve

| 1 | capacity | 25kg/h |

| 2 | Capacity | 18kw |

| 3 | Voltage | 380V,30A |

| 4 | SIZE | L750XW670XH1250mm |

| 5 | Weight | 100kg |

PS : Beverage filling machine, beverage filling machine is a plastic bottle beverage filling machine, automatic filling and capping machine, is a multi-functional beverage filling machine. It is used for filling carbonated beverages, soda water, salt soda and other carbonated beverages, as well as non-sparkling beverages such as fruit juice beverages and purified water. One machine has multiple functions and is a new type of filling machine with high practicability.

Welcome contact in any time ,customized line is our advantage

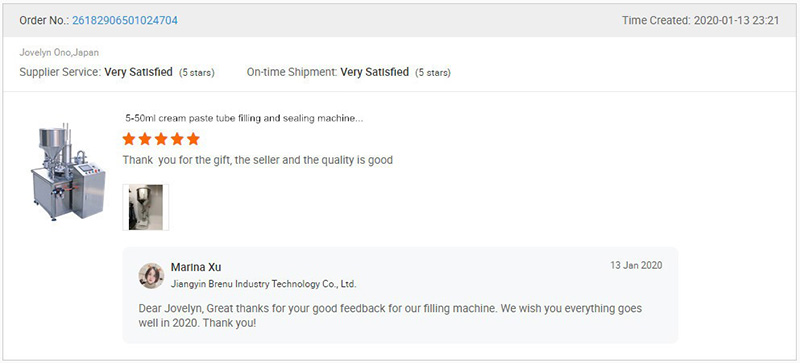

BUYER FEEDBACK

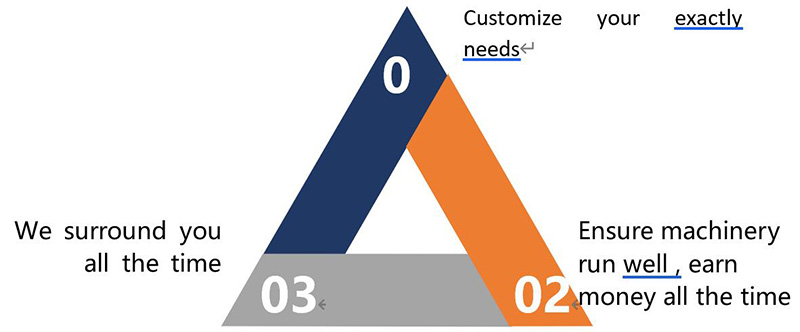

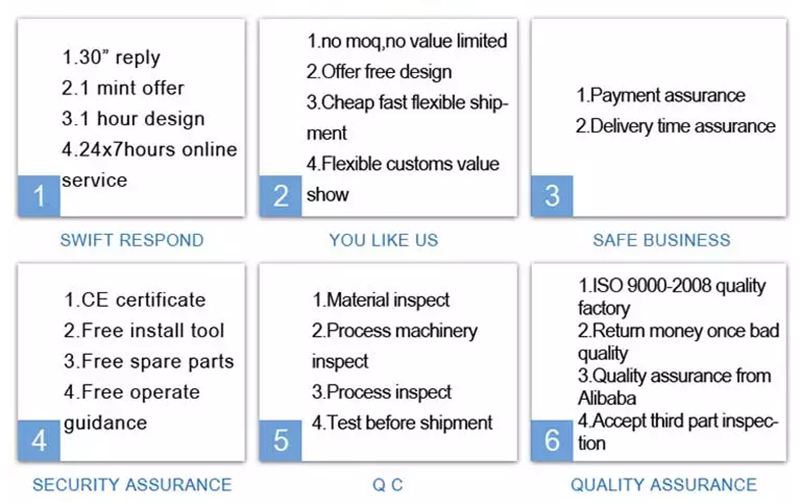

BRENU SERVICE

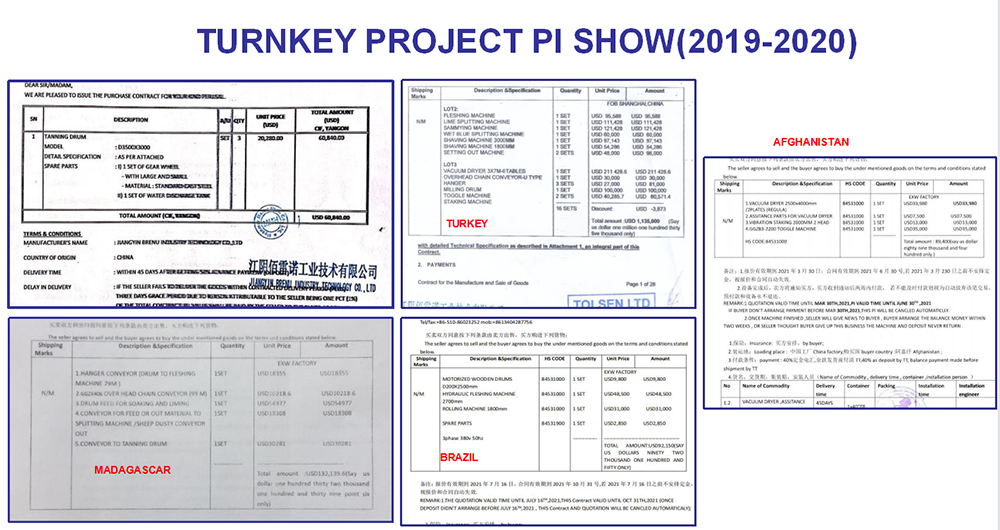

FACTORY SHOW

OUR PROMISE

SALES SERVICE ON LINE

① 24hours*365days*60minutes online service.

② team contact information for service .

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③ If there are quality or other problems with our products,our company's team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

MACHINERY PARTS GUARANTEE :

Our company guarantees that all parts of the machine are original and authentic. During the one-year warranty period, our company will provide customers with free replacement parts and consumables for non-human damaged parts and consumables. Replacement is available to customers at cost price. Our company promises to provide life-long service for customer equipment, and only charge basic material costs and corresponding labor costs outside the warranty period.

CHOOSE US YOU ARE BEST CHOICE :

SHOW OUR SERVICE TEAM PICTURE

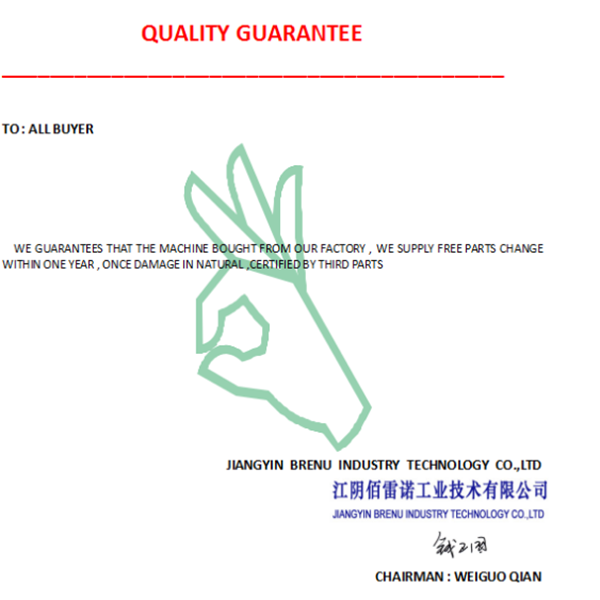

SHOW OUR GUARANTEE CERTIFICATE FROM CEO

SHOW OUR GUARANTEE CERTIFICATE FROM CEO

Welcome contact :

what's app:0086 13404287756

Quality guarantee :trade assurance by alibaba by manager and CEO

trade assurance protect : your money , delivery time and quality

JIANGYIN BRENU INDUSTRY TECHNOLOGY CO.,LTD

skype:belinna_2004mail:sales@brenupackmachine.com www.brenupackmachine.com