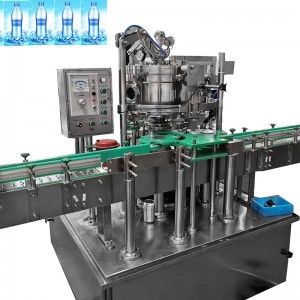

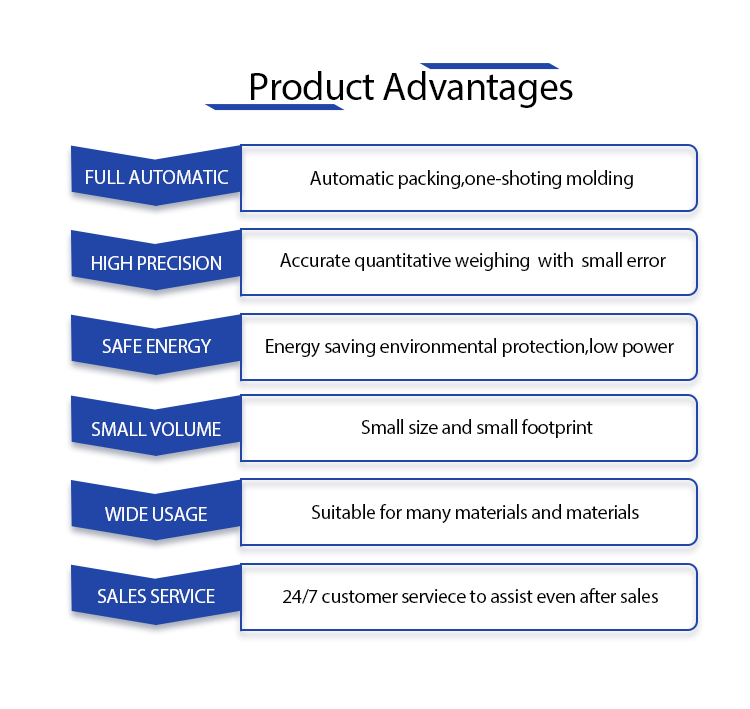

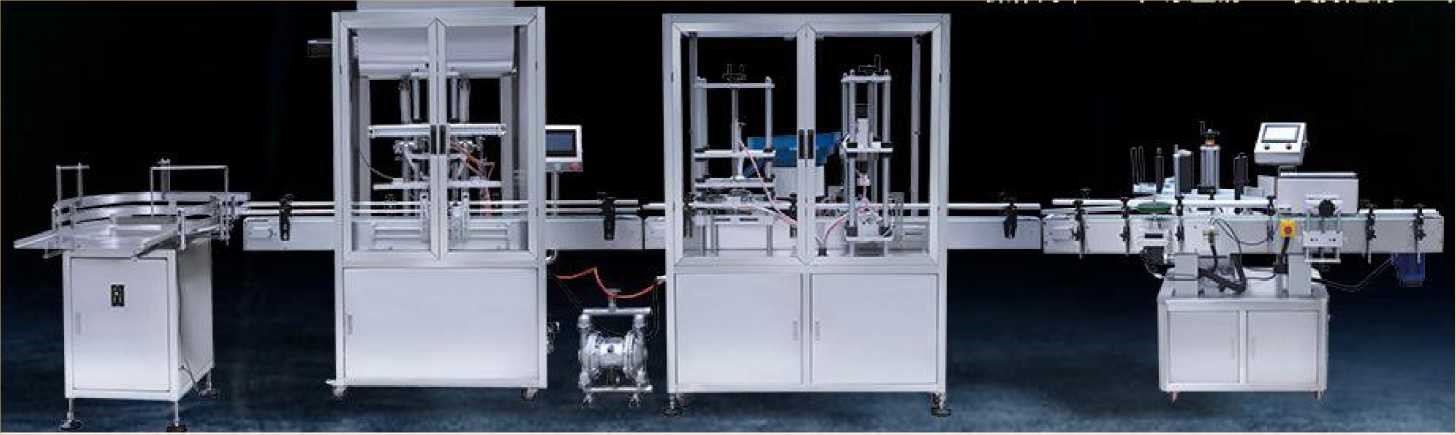

Auto liquid Filling Machine

The automatic liquid filling machine is an improved design based on the filling machine series products, and some additional functions have been added. Make the product more simple and convenient in the use of operation, accuracy error, installation adjustment, equipment cleaning, maintenance, etc. The automatic liquid filling machine can fill different high viscosity fluids. The machine has compact and reasonable design, simple and beautiful appearance, and convenient adjustment of filling volume.

With two simultaneous filling heads, filling materials is fast and accurate.

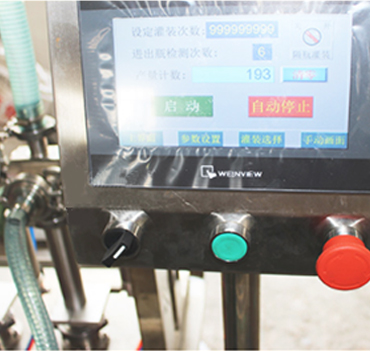

Convenient adjustment, no bottle no filling, accurate filling volume and counting function.

It adopts anti-drip and wire-drawing filling bulkhead, anti-foaming product filling and lifting system, positioning system to ensure bottle mouth positioning, and liquid level control system.

Products Show

1. Mainly used for liquid filling of lotion, care solution, oral solution, disinfectant, eye wash, nutrient solution, alcohol, injection, pesticide, medicine, perfume, edible oil, lubricant and special industries

2. DY single-head liquid filling machine is a reformed and innovative product of our company on the basis of referring to foreign advanced filling machine technology. Its structure is simpler and more reasonable, with high accuracy and easier operation.

3. Suitable for medicine, daily chemical, food, pesticide, beverage and special industries, it is an ideal liquid filling equipment

4. Semi-automatic piston liquid filling machine

5. The filling volume and filling speed can be adjusted arbitrarily, with high filling accuracy

| Power | 220V /200W |

| Applicable bottle height | 10-500(ml) |

| Applicable bottle diameter | ≥50mm |

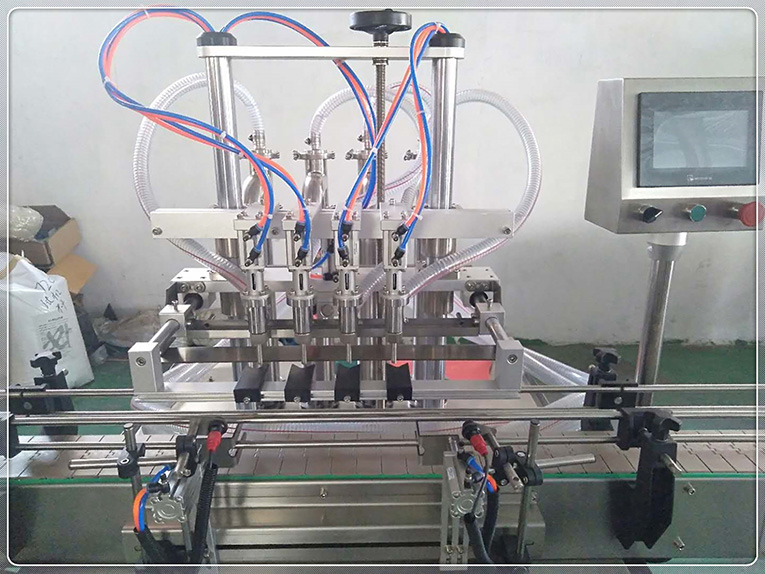

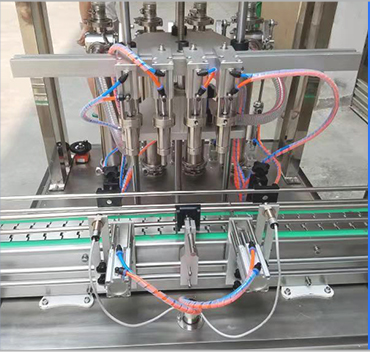

| Number of machine heads | Four heads |

| Filling range | 10 to 100, 20 to 300, 50 to 500, 100 to 1000, 500 to 3000, 1000 to 5000ml |

| Machine size | 1100x200x1500mm |

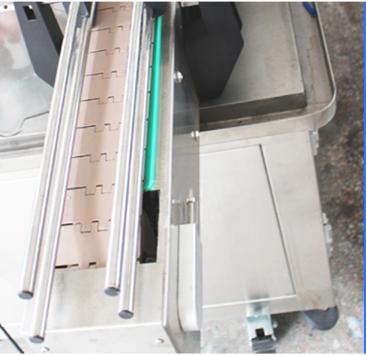

ANTI-DRIP FILLING NOZZLE

Ensure there is no drain or dripping during filling

EASY ADJUSTED FILLING SPEED OR VOLUME

No bottle and no filling function, automatic liquid level control and feeding

STRONG APPLICANBILITY

No need to change parts , can quickly adjust and change bottles of different shapes and specification

STAINLESS STEEL BODDY

Easy to disassemble , easy to clean , meet food hygiene requirements

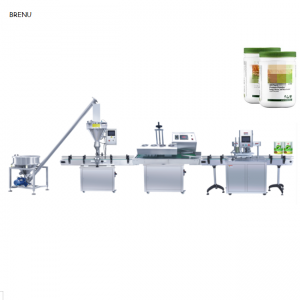

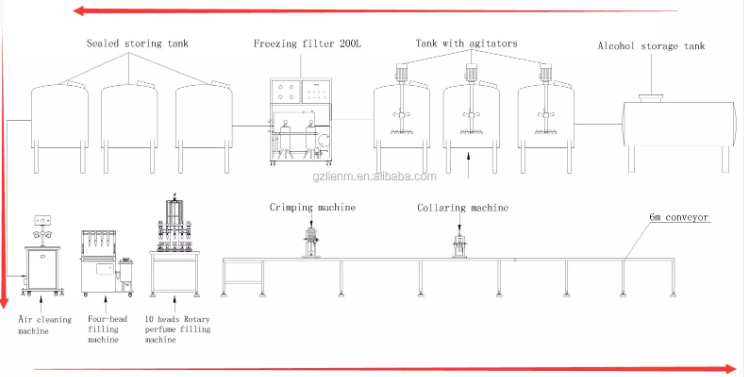

PERFUME WHOLE LINE SYSTEM

QC GUARANTEE

① all filling or capping machine from our factory ,QC personnel will carefully check the quality of the machine and do power-on test before the package leaves the warehouse.

②all filling or capping machine from our factory , There are special QC equipment to help QC personnel complete the inspection.

③all filling or capping machine from our factory ,QC stipulates that after each inspection, the quality inspection report must be filled in to ensure the quality of customers' goods.

AFTER-SALES SERVICE

① all filling or capping machine from our factory ,24hours*365days*60minutes online service. engineers, online sales, managers are always online .

② all filling or capping machine from our factory ,We have a complete set of after-sales service process.

Technical engineer :MR.JI (851439108@qq.com)

Online service:Lily(sales2@brenupackmachine.com)

Material Purchase manager:Tina(master@brenupackmachine.com)

Sales chief executive :Jessica(sales6@brenupackmachine.com)

③all filling or capping machine from our factory , If there are quality or other problems with our products,our company's team will discuss it together and solve it, if it is our responsibility, we will never refuse to make you satisfied.

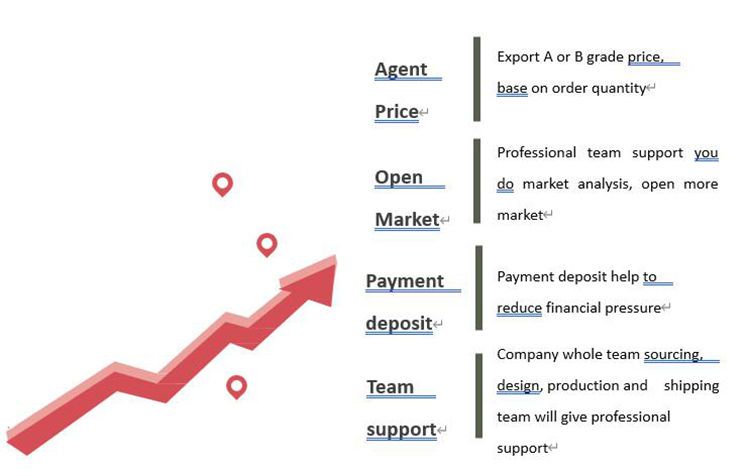

SPECIAL SERVICE FOR OUR AGENT

FAQ

1. Why choose us?

1.1- We have over 30 years experience on machinery making .

1.2- Our factory is located in Jiangsu province,more than 200 workers in our factory .

1.3- We sale good quality machines around the world with good service and got high reputation from our customer. Welcome to visit

our factory!

2.Can you customize machine ?

As a professional machinery manufacturer for more than 30 years,we have skilled OEM technique.

3. What about after sale service?

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

When machine has problem, We will solve basic questions by telephone, email, whatsapp, wechat and video call.

Customers showing us the picture or video of the problem. If the problem can be easily solved , we will send you solution by video

or pictures. If the problem out of your control, we will arrange engineer to your factory.

4.How about warranty and spare parts?

We provide 1 year guarantee and enough spare parts for the machine,and most of the parts can be found in local market also,also you

can buy from us if all the parts that over than 1 year guarantee.

5. How can you control the quality and delivery?

All our machines will be tested before packaging. Teaching video and packing pictures will be sent to you for checking,we promise

that our wooden packaging is strong enough and safety for long delivery .

6. What about the delivery time?

In stock machine:1-7days(depend on products).

MORE CUSTOMIZED FILLING MACHINE

PERFUME VACUUM LIQUID FILLING MACHINE

AUTO FILLING MACHINE

Contact us know more filling machine for more type machine including semi auto filling machine,full auto filling machine , customized design filling system : filling machine , capping machine ,sealing machine , labeling machine ,packing machine